For nearly all LGMG scissor lifts in North America, the Trojan T-105 battery is the superior replacement over the OEM option. Its higher cycle life and robust construction provide a lower total cost of ownership and significantly less downtime, making it the smarter choice for any serious maintenance operation.

</div>Symptoms & Identification: Spotting a Failing Battery Pack

Before you spend a dime on new batteries, you need to be certain that's the problem. Swapping a good battery pack because of a bad cable or a failing controller is a rookie mistake. A machine that's slow or won't hold a charge is telling you something.

Your operator will be the first to notice these classic symptoms:

- Drastically Shortened Run Times: The machine used to run a full shift, now it's dead by lunch. This is the #1 indicator of lost capacity.

- Sluggish Operation: Drive and lift functions feel weak and slow, even when the battery gauge shows a full charge.

- Machine Dies on Ramps or Under Load: As soon as the machine needs real amperage to climb an incline or lift a full platform, it cuts out. The weak pack can't handle the draw.

- Charger Fault Codes: The onboard charger is flashing an error, unable to bring the pack to the correct voltage because one or more cells are dead.

Tools Required

- Insulated Wrenches (Typically 1/2" or 13mm for terminals)

- Socket Set (for battery hold-down brackets)

- Wire Brush & Terminal Cleaner

- Battery Lifting Strap

- Torque Wrench

- Multimeter

Safety Warning

Disconnect the main negative battery terminal FIRST, then the main positive. When reinstalling, connect the main positive FIRST, then the negative. This prevents an arc if your wrench grounds against the chassis. Wear gloves and safety glasses—battery acid is not forgiving.

The Technical Guide: LGMG OEM vs. Trojan T-105

When your LGMG scissor lift is losing power halfway through a shift, you need a battery that's built for deep-cycling abuse, not just the cheapest option from the factory. The decision to stick with the LGMG OEM battery or upgrade to a Trojan T-105 comes down to a few key technical points that directly impact machine performance and your maintenance workload.

Key Performance Differences

Rental fleets and maintenance managers have made this call for years, and there's a reason the Trojan T-105 is the industry staple. Its specs are proven: at a 20-hour rate, it delivers 225 amp-hours (Ah), with a 447-minute capacity on a 25-amp draw. In shop talk, that means a solid 4-6 hours of real-world work per charge. You can read more insights from mechanics discussing scissor lift batteries on industry forums.

The bottom line is simple: While LGMG OEM batteries get the job done initially, Trojan batteries are built for the constant deep-cycling that scissor lifts endure, resulting in a longer service life and more consistent power delivery over time.

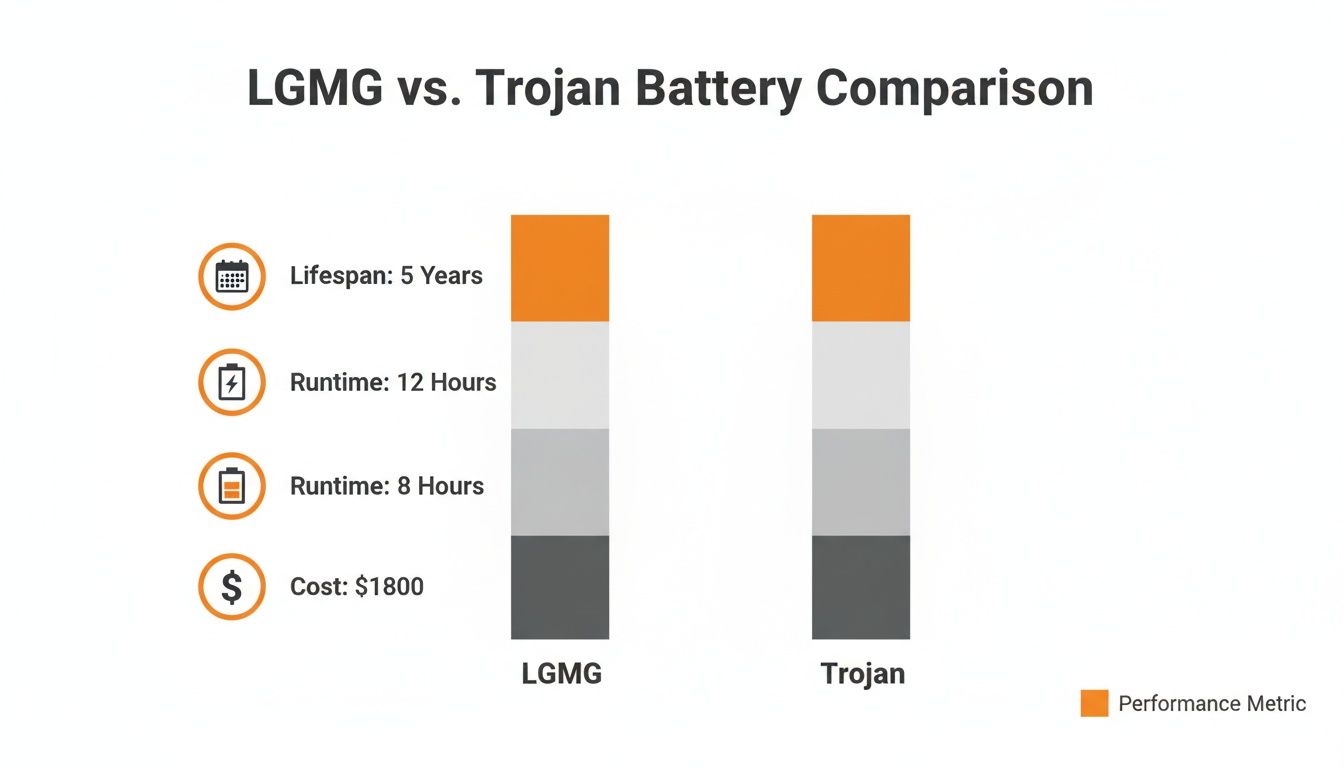

This graphic breaks down the essential metrics—lifespan, runtime, and overall cost.

The initial investment in Trojan batteries pays for itself through a longer lifespan and more dependable daily runtime.

LGMG OEM vs Trojan T-105 At-a-Glance

This table gives you a direct comparison of the critical specifications. These are the numbers that determine whether your machine finishes the day or dies on the job.

| Specification | LGMG OEM Battery | Trojan T-105 | | :--- | :--- | :--- | | Typical Cycle Life | 400-600 Cycles | 700-900+ Cycles | | Amp-Hour Capacity (20-Hr Rate) | ~210 Ah (Varies by supplier) | 225 Ah | | Construction | Standard plate construction | Alpha Plus® Paste, T2 Technology™ | | Maintenance Requirement | Frequent manual watering | Reduced watering; HydroLink™ compatible | | Upfront Cost | Lower | Higher | | Long-Term Value | Lower due to shorter life | Higher due to longevity & reliability |

The specs don't lie. The Trojan's superior cycle life and robust construction are engineered for the demanding environment of a rental fleet or a busy job site.

Identifying Failing Scissor Lift Batteries

Before you swap the pack, you need to be damn sure that's the problem. Wasting time and money on a misdiagnosis is a quick way to get your boss on your back.

Technical and Visual Indicators

Beyond what the operator feels, there are clear technical signs you can spot right in the shop. These are the red flags that confirm the battery pack is on its way out.

A healthy 24V battery pack (four 6V batteries) should read around 25.2-25.6V fully charged and shouldn't drop below 24V under a light load. If you see a significant voltage drop the instant you activate a function, you've found your problem.

Look for these signs on the machine itself:

- Low Voltage Under Load: Grab a multimeter and check the pack voltage. Test it static, then hit the main lift function and watch for a severe voltage drop. A dip of more than a couple of volts signals a weak pack. For more complex electrical issues, our troubleshooting guides can help you pinpoint the exact cause.

- Swollen or Leaking Battery Cases: A quick visual inspection is critical. Look for bulging or cracked battery cases—a clear sign of internal damage from overcharging, freezing, or sulfation.

- Corroded Terminals: Heavy, fuzzy corrosion on the battery posts and cable ends indicates excessive gassing and a poor connection. This alone can mimic complete battery failure.

If you're seeing a combination of these symptoms, you can be confident that replacing the scissor lift batteries is the right call. It's not a controller issue; it's a pure lack of available power.

Technical Deep Dive: Amp-Hours, Cycle Life, and Durability

Let's cut the marketing fluff and get down to the engineering. When you're comparing an LGMG OEM battery to a Trojan, you're looking at fundamental differences in chemistry and construction that determine whether your scissor lift works a full day or dies before lunch.

The numbers on the spec sheet—amp-hours and cycle life—are where the real story is told. They directly translate to runtime and your long-term cost.

Decoding Amp-Hour Ratings for Real-World Runtime

A battery's stated capacity changes based on how fast you drain it. A slow drain yields more total power than a fast, heavy one.

- 20-Hour Rate (C/20): This is the industry standard and the most relevant number for scissor lift work. The Trojan T-105 is rated at 225 Ah at this rate.

- 100-Hour Rate (C/100): This number is always higher but less realistic for our application. You’ll never be drawing power that slowly on a job site.

Standard LGMG OEM batteries often have a 20-hour rating closer to 210 Ah. While a 15 Ah difference might not sound like much, it's the gap that separates finishing the last hour of work from having to stop and recharge.

Think of it this way: The extra 15 Ah in the Trojan is your reserve tank. It's the power that gets your machine through heavy lifting and driving cycles late in the day when a standard battery would have already hit low-voltage cutoff.

The Science Behind Durability and Cycle Life

Why does a Trojan battery consistently outlast a standard OEM battery? The answer is inside the case, in the paste and separators. These technologies fight the two biggest killers of deep-cycle batteries: plate degradation and shorting.

Trojan's Key Technologies:

- Alpha Plus® Paste with T2 Technology™: This is the active material on the lead grids. Trojan's proprietary paste formula is denser, resisting shedding during the deep charge/discharge cycles a scissor lift battery endures. Less shedding means the battery maintains its capacity for more cycles.

- Maxguard® T2 Separator: This insulating material sits between the positive and negative plates. If it fails, the plates touch and short a cell. Trojan's separator is thicker and more robust, offering better protection against the vibration and jostling on a construction site.

In contrast, many standard OEM batteries use a more conventional paste and thinner separators to keep costs down. They work fine initially but can't withstand the abuse of deep-cycling for as long. This superior internal construction is why a Trojan T-105 can reliably deliver 700-900+ cycles, while a standard OEM battery is often giving up around 400-600 cycles. Making the right choice in replacing scissor lift batteries comes down to understanding that investing in better internal components leads to a longer service life and less downtime.

Installation and Compatibility Guide

You've diagnosed the batteries as the culprit. Time for the swap. Getting this right means the difference between a reliable machine and one that'll give you electrical headaches for months. A sloppy job can kill your new batteries or fry the lift’s controller.

The Step-by-Step Battery Swap Procedure

Follow these steps exactly. No shortcuts.

- Secure the Machine: Park the scissor lift on a flat, level surface. Chock the wheels, pull the key, and engage the emergency stop buttons on both ground and platform controls.

- Verify Compatibility: Before a single wrench turns, confirm the new batteries will fit. The battery trays on LGMG lifts are notoriously snug. The Trojan T-105 is the industry's go-to for 24V (four 6V batteries) systems. For newer 48V systems, you're looking at eight 6V batteries. Note: Components may vary by Gen 1 vs Gen 2 series. Verify with your parts manual.

- Disconnect and Remove: Swing open the battery compartment. Find the main negative cable for the entire pack and disconnect it first. Then, disconnect the main positive. Now you can safely remove all the jumper cables. Loosen the hold-down brackets. Using a battery strap, lift the old batteries out one by one.

- Clean the Compartment: Mix baking soda and water to neutralize any spilled acid in the tray. Scrub it out, rinse, and let it dry completely. Use a wire brush on every single cable terminal until it shines. A clean connection is a good connection.

- Install New Batteries: Place the new batteries into the tray, paying attention to their orientation for the series connection. Re-install the hold-down brackets. Do not overtighten—you want them snug, not crushed.

- Connect and Torque: Reconnect the jumper cables to link the batteries in series (positive-to-negative). Now, attach the main positive machine cable to the correct battery post. Finally, attach the main negative cable. Using a torque wrench, tighten every terminal nut to 95-105 in-lbs. Do not guess. Overtightening will snap the lead post; undertightening creates a poor connection that can melt the terminal.

- Final Checks: Check the total voltage across the main positive and negative terminals. A fresh 24V pack should read around 25.2V. Release the e-stops, power on the machine, and confirm proper function.

The Part You Need

The biggest operational killer isn't a dead battery—it's the lead time to get a new one. The dealer will quote you a 6 to 8-week wait for parts from overseas. Downtime is the enemy, and waiting on a slow boat from China is a battle you've already lost.

China Lift Supply stocks the Trojan T-105 battery and other OEM-compatible parts in our US warehouse to eliminate that lead time.

LGMG Scissor Lift Battery Replacement - Trojan T105 (In-Stock US) Check Price & Availability

FAQs From the Shop Floor

Here are straight answers to the questions we get all the time from mechanics dealing with battery swaps.

Can I Mix Old and New Batteries in the Same Pack?

Hard no. Never mix old and new batteries, or different brands/capacities. A single weak battery in the string acts like an anchor, dragging down the performance of the entire pack. It leads to uneven charging and discharging, which will cook your brand-new batteries in a fraction of their expected service life.

Is It Worth Upgrading From Flooded Lead-Acid to AGM?

For most scissor lift applications, a high-quality flooded lead-acid battery like the Trojan T-105 offers the best balance of performance, longevity, and cost. While AGM batteries are maintenance-free, they come at a premium price and can be sensitive to overcharging—a real risk with some of the simpler onboard chargers found on these lifts. Stick with what's proven.

How Do I Know Which Trojan Battery Fits My LGMG Lift?

The go-to replacement for LGMG's 6V batteries is the Trojan T-105, and for 8V systems, it's the T-875. But you must confirm fitment. Physically measure the old batteries and check the terminal type. Compare those specs to the manufacturer's data sheets. When in doubt, call us with your machine's model and serial number, and we'll verify it for you.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: Check Price & Availability.