The Quick Diagnosis

If you plug in your Dingli, LGMG, or Sinoboom lift and the charger won't engage, the battery pack's total voltage has likely dropped below the charger's minimum safety threshold. A single dead cell in one of the 6V batteries is usually the culprit, dragging the entire 24V or 48V pack down. Your first step is to check each battery individually with a multimeter to find the outlier.

Symptoms & Identification

Before you grab your tools, confirm you're on the right track. Here's what you'll see on the shop floor:

- The charger lights don't turn on at all when plugged into the lift.

- The machine is completely dead—no power to the platform controls or drive functions.

- The charger works on another identical machine, confirming the charger itself is not the problem.

- The charger may flash a fault code related to low battery voltage (refer to the charger's manual).

Tools Required

- Digital Multimeter (DMM): Non-negotiable for accurate voltage checks.

- Insulated Wrench Set: To prevent shorting terminals.

- Low-Amperage "Dumb" Manual Charger: A 2-10 amp charger for boost charging.

- Battery Hydrometer: Essential for testing specific gravity in flooded lead-acid cells.

- Wire Brush / Terminal Cleaner: For removing corrosion.

- ANSI-approved Safety Glasses & Acid-Resistant Gloves.

Safety Warning

Disconnect the negative battery terminal of the entire pack first. These batteries vent explosive hydrogen gas, especially during charging. A single spark from a dropped wrench can cause a catastrophic explosion. Work in a well-ventilated area and always connect charger clamps to the battery terminals before plugging the charger into the AC outlet to prevent sparks.

The Technical Guide: Step-by-Step Diagnosis & Revival

Step 1: Verify the Basics (No-Brainer Checks)

- Check AC Power: Confirm the wall outlet has power by plugging in a known-good tool or light.

- Inspect Connections: Put your eyes on the battery pack. Look for obvious signs of failure like swollen cases, melted terminals, or heavy, cauliflower-like corrosion. Ensure all battery cables are tight and clean. A loose or corroded main connection can stop a charge cold.

Step 2: Measure Total Pack Voltage

- Set your multimeter to DC Voltage.

- Place the red probe on the main positive terminal of the entire battery pack and the black probe on the main negative terminal.

- For a standard 24V system (four 6V batteries), a deeply discharged pack might read as low as 18-20V. Most "smart" chargers on LGMG or Sinoboom lifts require a minimum of 20-21V to even begin a charge cycle. If your reading is below this, you've found why the charger won't engage.

Step 3: Isolate the Bad Battery

- With the batteries still connected in series, test each one individually.

- Place your multimeter probes across the positive and negative terminals of the first battery. A discharged but healthy 6V battery should still read around 5.0V - 5.5V.

- Repeat this for all four batteries.

- Look for the outlier. If three batteries read ~5.2V and one reads 0.8V (or a flat 0V), you've found the battery with a dead cell. That single failed battery is dragging the whole pack down.

Mechanic's Tip: For flooded batteries, use your hydrometer. Voltage can sometimes be misleading. A fully charged cell reads ~1.265 specific gravity, while a dead cell will be ~1.120. If one cell's gravity is way off from the others in the same battery, that battery is internally shorted and must be replaced.

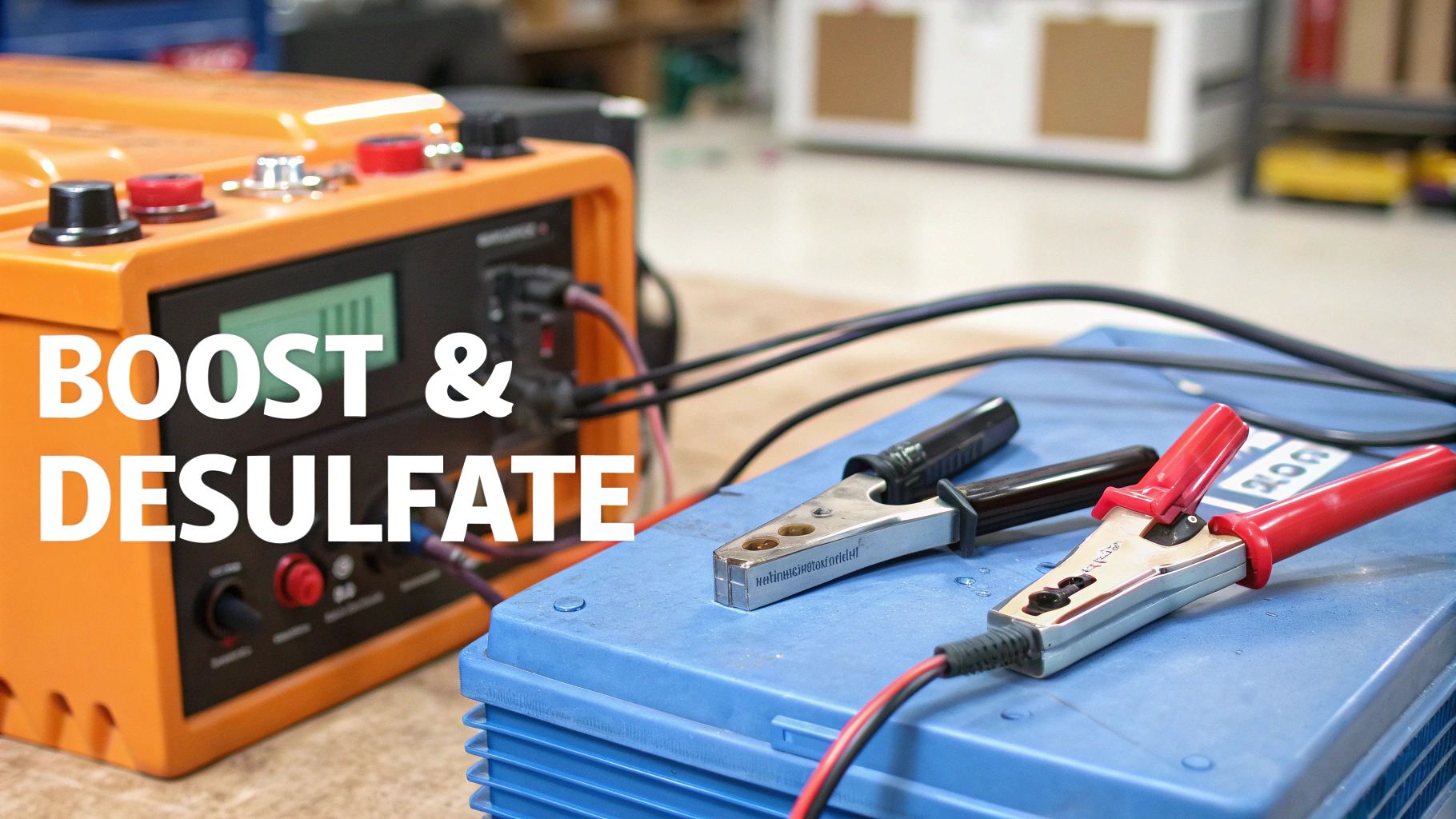

Step 4: Attempt a "Boost" Charge (If No Dead Cells Found)

If all batteries show similar, low voltage readings (e.g., all are around 4.5V), the pack may be salvageable.

- Connect your low-amperage manual ("dumb") charger directly to the main positive and negative terminals of the entire pack. Set it to a low setting, like 2-5 amps.

- Plug the charger in and let it run. This bypasses the smart charger's low-voltage cutoff.

- Monitor the pack voltage with your multimeter every 30-60 minutes.

- Once the total pack voltage climbs above the ~21V threshold, unplug the manual charger and immediately plug in the machine's onboard charger. It should now recognize the pack and begin a normal charge cycle.

- Monitor for heat. If any battery gets hot to the touch during this process, stop immediately. It indicates an internal short, which is a serious fire hazard.

Step 5: When to Call It Quits

You can't save them all. It's time to replace the pack if:

- One or more batteries read 0V or close to it. This indicates a dead internal short.

- A battery case is visibly cracked or swollen.

- The pack voltage refuses to rise after several hours on a boost charge. The plates are too sulfated.

- You confirm a dead cell with a hydrometer.

The Golden Rule: Always replace deep-cycle batteries as a complete, matched set. Mixing one new battery with three old ones creates an imbalance that will destroy the new battery and overwork the old ones. You’ll be doing the job again in six months.

Note: Components may vary by Gen 1 vs Gen 2 series. Verify with your parts manual.

The Part You Need

For most 19-ft and 26-ft Chinese lifts like the LGMG SS0507E or Sinoboom 1932ME, you'll need a set of four 6V deep-cycle batteries (Flooded or AGM). The villain here is the 6-8 week lead time from the dealer, which means unacceptable downtime.

Constraint: China Lift Supply stocks OEM-compatible battery sets and chargers in the US, ready for same-day shipping to get your machine back to work. We also carry compatible scissor lift chargers if you diagnose a faulty charger as the root cause.

When It's Time to Call It Quits and Get a Replacement

<iframe width="100%" style="aspect-ratio: 16 / 9;" src="https://www.youtube.com/embed/YC--MLNIbik" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>Look, I'm all for bringing a battery pack back from the brink, but you have to know when to throw in the towel. Some batteries are just too far gone, and trying to revive them is not only a waste of time but a serious safety risk.

If you’ve hooked up your multimeter and one battery reads a flat 0V, it's a goner. That’s a tell-tale sign of a dead short internally. Another dead giveaway is a battery that gets scorching hot the second you try to apply a charge. Don't even think about trying to "fix" it—that thing is a fire hazard waiting to happen. Pull it out and tag it for recycling.

The other dead end is stubborn sulfation. If you've had the pack on a desulfator for 48 hours straight and the voltage hasn't budged one bit, the damage is likely permanent. At that point, the sulfate crystals have hardened to the point of no return, choking the lead plates. You’re just burning electricity trying to revive a corpse.

Why You Never Replace Just One Battery

I see this mistake all the time. A crew diagnoses one bad battery in a set of four and, trying to save a few bucks, they just swap out the single dead one. This is a classic rookie move that will absolutely cost you more down the road.

Think about it: you're mixing one brand-new, full-capacity battery with three older, weaker ones. It creates a massive imbalance. The charger sees the pack as a whole and will constantly overcharge the new battery while undercharging the old ones. You'll cook the new battery in a matter of months and put even more strain on the tired ones. I guarantee you’ll be tearing into that lift again before you know it.

The Golden Rule of the Shop: Always, always replace deep-cycle batteries as a complete, matched set. It's the only way to ensure they charge and discharge in balance, giving you the full service life you paid for.

Getting the Right Parts Without the Weeks-Long Wait

For common Chinese lifts like the LGMG SS0507E, Sinoboom 1932ME, or Dingli JCPT0807AC, you're typically looking at a set of four 6V deep-cycle batteries. The big headache is waiting six to eight weeks for the dealer to ship them from overseas. That's downtime nobody can afford. We keep high-quality, OEM-compatible AGM and flooded lead-acid batteries stocked right here in the US.

It’s also worth noting how lithium-ion technology is changing the game. While we can often revive traditional lead-acid batteries, a dead lithium pack with a fried Battery Management System (BMS) is a completely different animal. Repair is rarely an option; replacement is the standard procedure.

Whether you've decided you need a fresh set of batteries or you've realized your charger is the real culprit, you can't have your machine sitting idle. Find exactly what you need by browsing our full inventory of in-stock scissor lift parts that we can ship out the same day.

Common Questions About Reviving Dead Scissor Lift Batteries

When you’re staring down a dead scissor lift that won’t take a charge, you've got questions. We hear the same ones all the time from mechanics and fleet managers trying to get their equipment back on the line. Let's get right to it—no fluff, just the answers you need.

Can I Replace Just One Bad Battery In A 24V Pack?

I know it’s tempting. You see one bad battery and think you can save a few hundred bucks by only swapping that single unit. But trust me, this is a classic mistake that will cost you far more in the long run.

Mixing a brand-new battery with three older, weaker ones throws the entire pack into a state of massive electrical imbalance. The charger sees the pack as a whole, so it will constantly overcharge the new battery (which has lower internal resistance) and undercharge the old ones. The new battery gets cooked, and the old ones keep degrading.

You’ll be right back where you started in a few months, only this time you're replacing the whole set and you've wasted the money spent on that single battery. Always replace batteries as a complete, matched set. It’s the only way to guarantee balanced performance and get the full service life you paid for.

How Do I Know If A Battery Is Sulfated Or Just Discharged?

This is where your diagnostic work really pays off. A deeply discharged battery and a heavily sulfated one can look identical on a multimeter at first glance—both will show very low voltage. The key difference is how they react when you try to charge them.

A battery that's just deeply discharged will eventually accept a slow, low-amp charge from a good manual charger. You'll see the voltage gradually start to climb over a few hours. It’s a slow process, but it works.

A sulfated battery, however, is a different beast. The lead sulfate crystals have hardened on the plates, acting like an insulator and physically blocking the battery from taking a charge. When you hook up a manual charger, the voltage will barely budge, even after hours. If you're working with flooded cells, your hydrometer will confirm it with stubbornly low specific gravity readings that refuse to improve. That's your tell-tale sign that the sulfation is probably irreversible and the battery is junk.

Is It Safe To Jump-Start A Scissor Lift From A Truck?

No. Just… no. Never, ever do this. This is one of the most dangerous things you can do to any piece of electric equipment.

Think about it: a truck uses a 12V starting battery designed to deliver a massive, high-amperage jolt for a few seconds to crank an engine. Your scissor lift runs on a 24V or 48V deep-cycle system built for slow, steady power. They are fundamentally different.

Here’s the breakdown of what goes wrong:

- Voltage Mismatch: A 12V source won't do a thing for a 24V system. Best case, nothing happens.

- Current Overload: Worst case, the uncontrolled high amperage from the truck's system fries your lift's sensitive electronics. I’m talking controllers, contactors, and the charger itself. You've just turned a battery problem into a multi-thousand-dollar repair.

- Explosion Risk: You're risking melted cables and sparks right next to batteries that could be venting explosive hydrogen gas.

It’s just not worth it. Use the right tool for the job: a voltage-appropriate, compatible battery charger designed for deep-cycle systems.

What Is The Difference Between AGM And Flooded Batteries?

Both are lead-acid batteries, but the way they're built inside makes a huge difference. You need to know which type you have because they require different charging profiles.

- Flooded Lead-Acid Batteries: These are your traditional "wet cell" batteries. They have liquid electrolyte (sulfuric acid and water) sloshing around inside, and you can access it through removable caps. They're cheaper upfront but demand regular maintenance—checking and topping off water levels is non-negotiable. They also have to be installed upright, or they'll spill.

- AGM (Absorbent Glass Mat) Batteries: In an AGM battery, the electrolyte is soaked up into fine fiberglass mats squeezed between the lead plates. This design makes them sealed, spill-proof, and completely maintenance-free. They handle vibration much better and can often take deeper discharges than their flooded cousins.

For a busy rental fleet or a rough-and-tumble job site, AGM batteries are often the smarter play. The higher initial cost is usually offset by their durability and the peace of mind that comes from not having to rely on an operator to remember to water them. Just be absolutely sure your charger is set to the correct "AGM" profile to avoid damaging them.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: https://www.chinaliftsupply.com.