Symptoms & Identification

Before you grab a wrench, listen to what the machine is telling you. A correct diagnosis upfront saves hours of guesswork and prevents replacing a perfectly good pump. Downtime is the enemy; a fast, accurate diagnosis gets the machine back to work.

- Loud Whining or Grinding Noise: Classic pump starvation (cavitation). The pump is sucking air instead of oil. Check the fluid level, suction line for blockages, and the tank breather cap.

- Slow or Weak Lift Function: You're losing pressure. This points to a worn-out pump, a faulty relief valve, or internal bypassing in the lift cylinders.

- No Hydraulic Function at All: If the pump motor contactor pulls in but nothing happens, you've likely got a sheared pump shaft or a seized motor. If the contactor isn't activating, it's an electrical issue, not hydraulic.

- Overheating Hydraulic Fluid: A hot hydraulic tank means major inefficiency. Fluid is being forced through a restriction, likely a relief valve that's stuck partially open and constantly bypassing.

Tools Required

- 5,000 PSI Hydraulic Pressure Gauge with Tee Fittings

- Wrench set (for drain plugs and filter housings)

- Clean 5-gallon drain pan

- Torque wrench

- Clean, lint-free rags

Safety Warning

CRITICAL: Always lower the platform completely and chock the wheels before working on the hydraulic system. Hydraulic fluid can be under thousands of PSI and hot enough to cause severe burns. Relieve all system pressure before loosening any fittings.

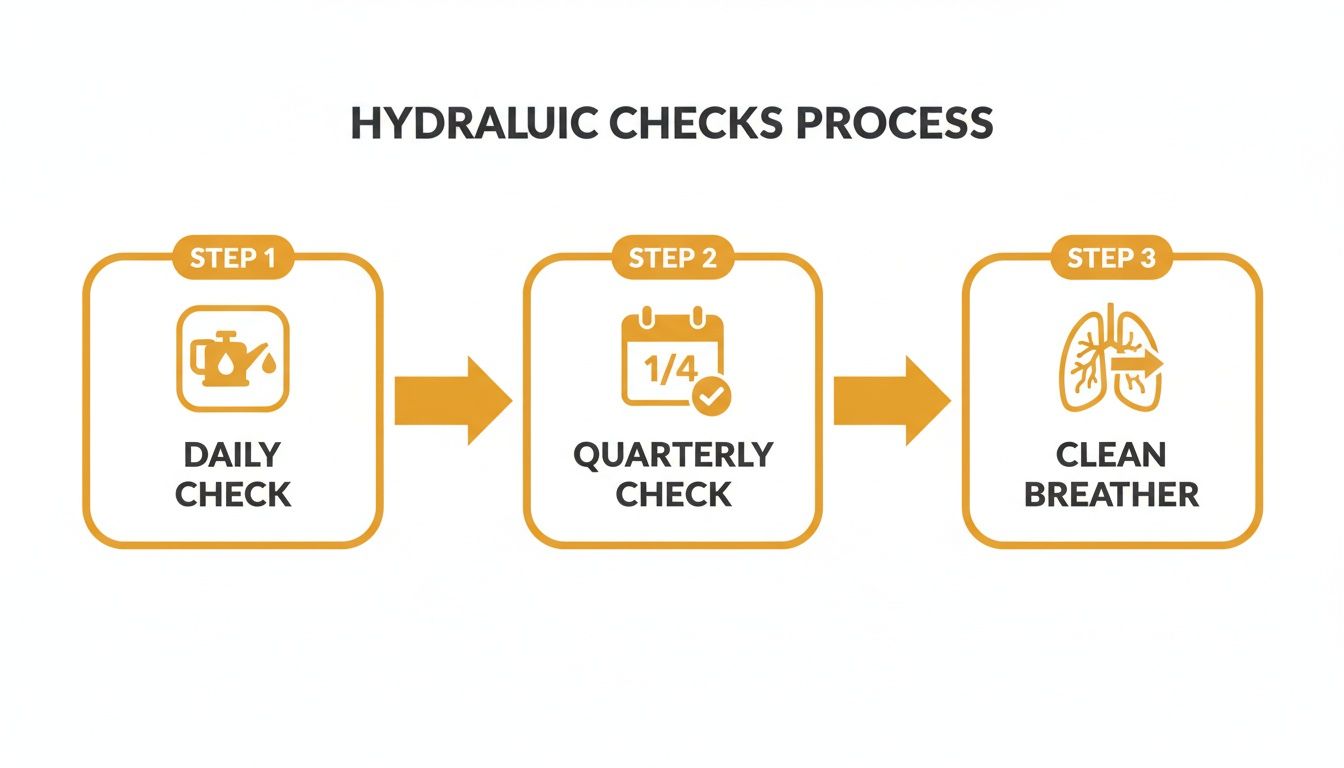

The Technical Guide: Step-by-Step Maintenance

Prevention is always cheaper than a new pump. These daily and scheduled checks are non-negotiable if you want to avoid downtime.

The 8-Hour Daily Walkaround

This takes five minutes and can save you thousands.

- Check Hydraulic Oil Level: With the platform fully lowered and the machine on a level surface, check the sight glass. The fluid must be in the middle. Low fluid is the #1 cause of pump cavitation and failure.

- Visual Leak Inspection: Walk the machine. Look for any fluid sheen at hose crimps, cylinder bases, and the pump/motor assembly. A small weep today is a high-pressure blowout tomorrow.

- Listen to the Pump: On first startup, a healthy pump has a low, consistent hum. A high-pitched whine or grinding means it's starving. Shut it down immediately.

The 250-Hour Quarterly Inspection

Every 250 hours, you need to evaluate the health of the hydraulic fluid itself.

- Pull an Oil Sample: Healthy hydraulic fluid is clear with a slight amber tint.

- Check for Water: If the oil is milky or cloudy, you have water contamination from pressure washing or condensation. Water destroys the oil's lubricating properties and corrodes internal components.

- Check for Heat Damage: If the oil is dark brown/black and smells burnt, it has suffered thermal breakdown. This turns it into sludge that clogs filters and passages. This is a symptom of a larger issue, like a bypassing relief valve.

- Clean the Breather Cap: The tank breather allows air to enter as the fluid level drops. If it's clogged with dirt, it creates a vacuum, forcing the pump to work harder. Remove the cap, clean it with a solvent, and blow it out with compressed air.

The 500-Hour Service: Replace the Breather

Every 500 hours, replace the hydraulic tank breather cap. A clogged breather restricts airflow, causing pump cavitation and reducing its lifespan by up to 30%.

- Lower the platform completely.

- Clean the area around the old breather cap to prevent dirt from entering the tank.

- Unscrew the old cap and screw on the new one hand-tight.

The 1000-Hour Service: Fluid and Filter Change

At 1,000 hours, it's time for a full hydraulic fluid and filter change. Old, broken-down oil accelerates wear on every component.

- Drain the Old Oil: Place a drain pan under the tank, remove the drain plug and the breather cap to allow air in. Let it drain completely.

- Replace the Return Filter: While draining, unscrew the return filter housing. Remove the old element and wipe the housing clean.

- Install the New Filter: Lightly lubricate the new filter's O-ring with clean hydraulic oil. Install the new element and tighten the housing. Refer to your specific service manual for torque values—do not overtighten.

- Refill with Fresh Oil: Replace the drain plug. Using a clean funnel, refill the tank with fresh ISO VG46 hydraulic oil until the level is in the middle of the sight glass.

- Cycle the System: Start the machine and run the lift up and down several times to purge trapped air.

- Final Level Check: Lower the platform completely and re-check the oil level. Top off if necessary.

The 2000-Hour Overhaul: Seals and Hoses

This service is critical for long-term reliability. A simple drain and fill isn't enough; contaminants are embedded throughout the system. A full system flush is required to remove sludge from cylinders and manifolds.

- Flush the System: Drain the tank and cycle all functions to push out old fluid. A filtering cart is ideal for scrubbing the lines clean before refilling.

- Replace Pump Seals: The main pump shaft seal will be hard and brittle. Replacing it is cheap insurance against a major leak.

- Inspect All Hoses: Check every hose for cracks, bulges, or weeping at the crimp fittings. Replace any that look questionable.

- Test the Pressure Relief Valve: Remove, clean, and bench-test the main relief valve to ensure it opens at the correct pressure (typically around 2,500 PSI). An out-of-spec valve causes poor performance or dangerous over-pressurization.

The Part You Need

The hydraulic return filter element and breather cap are critical wear items. Waiting 6 weeks for a dealer to ship them from China means unacceptable downtime.

Constraint: China Lift Supply stocks the OEM-equivalent filters and caps you need in the US, ready for same-day shipping.

Advanced Troubleshooting for Pump Failures

<iframe width="100%" style="aspect-ratio: 16 / 9;" src="https://www.youtube.com/embed/Av5ZbahEBRk" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>When routine checks don't solve the problem, you need to diagnose properly. Over 70% of "pump problems" are caused by something else. The pump is often the victim, not the culprit.

Pressure Testing the Right Way

If lift functions are slow, don't guess. Test.

- Connect a 5,000 PSI gauge with a tee fitting into the pressure line directly off the pump.

- Deadhead a function (e.g., lift to the top of its stroke) to force the system over the main relief valve.

- Read the pressure. It should jump to the system relief setting, around 2,500 PSI. If it does, your pump is good; the problem is downstream (bypassing control valve or cylinder seal). If you can't build pressure, then the pump is the likely issue.

Decoding Pump Noises: Cavitation vs. Aeration

A whining or grinding noise is either cavitation or aeration.

- Cavitation is fluid starvation. The pump is trying to move more oil than the suction line can deliver. This is caused by a low fluid level, a clogged suction filter, or a blocked tank breather.

- Aeration is an air leak. Air is being sucked into the system through a loose fitting or bad shaft seal on the suction side.

The Diagnosis: Check the oil in the tank. Aerated oil will look milky or foamy. Cavitation doesn't always make the oil foamy but often makes the pump casing very hot.

Tracing Contamination

If you find metal in the oil, you have a hard part failure. You must find the source.

- Brass/Bronze Specks: Classic sign of a gear pump wearing out its internal plates. The pump is the source.

- Shiny Steel Flakes: Often from a failing bearing, not necessarily in the pump.

- Black Rubber Pieces: A hose is failing from the inside out, or a seal has failed.

After a catastrophic failure, a full system flush is non-negotiable. Otherwise, the debris will destroy the new pump.

The Big One: Managing the 2000-Hour Overhaul

The 2000-hour service is the most critical overhaul your Sinoboom 1932 will get. It's the difference between planned maintenance and an emergency breakdown. Skipping this is setting the machine up for catastrophic failure.

Beyond an Oil Change: The Full System Flush

After 2,000 hours, microscopic metal and sludge are embedded throughout the system. A simple drain won't remove it. You need a full system flush, cycling all cylinders to push out the old fluid and using a filtering cart to scrub the lines clean before refilling with fresh ISO VG46 oil.

Core Wear Components to Inspect and Replace

At 2,000 hours, these components are at their wear limits. Replace them proactively.

- Pump Seals: The main shaft seal is hard and brittle. Replace it to prevent a massive leak.

- Hydraulic Hoses: Inspect every hose for cracks, bulges, or weeping at the fittings. If it looks questionable, replace it.

- Pressure Relief Valve: Pull, clean, and bench-test it to verify it opens at the correct pressure.

Strictly following this 2,000-hour service can extend the life of the main hydraulic pump by 50% or more. The biggest challenge is often getting the parts.

Common Questions on Sinoboom Hydraulic Maintenance

Here are the straight answers to the most common questions we get.

Can I Use a Different Hydraulic Oil?

No. Stick with ISO VG46 hydraulic fluid. Using a different viscosity or a universal fluid will cause premature wear, overheating, and pump failure. The tolerances are too tight. It's not worth the risk.

Why Does My New Pump Whine?

You have an air leak on the suction side. A poorly seated O-ring or a loose fitting is the usual cause. A whining new pump is a cry for help—shut it down and find that air leak. Before starting a new pump, always pre-fill the suction hose with clean oil to prevent a dry start.

What is the Correct System Pressure?

Approximately 2,500 PSI (17.2 MPa). Verify this with a gauge teed into the pressure line. If pressure is low, check and adjust the main relief valve. Don't guess. Over-pressurizing the system will blow seals.

How Often Should I Really Change the Filter?

The book says 1,000 hours. Stick to it. Once the return filter goes into bypass, it's dumping all contaminants directly back into the tank to be circulated through your new pump. A $50 filter protects a multi-thousand-dollar system. It's the cheapest insurance you can buy.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: [Link Placeholder].