If your LGMG T72J is showing signs of slow or jerky hydraulic functions, a clogged main hydraulic return filter is the prime suspect. You will find this spin-on filter housed inside the hydraulic tank, accessible through a top-side service cover on the chassis. This guide provides the exact location, specs, and replacement procedure to get your machine running correctly.

<div class="feature-box"> **The Quick Diagnosis**A restricted hydraulic filter is starving your pump for oil. Symptoms include sluggish boom functions, a whining pump, and an overheating system. The part you need is a 10-micron spin-on filter with a 1-1/2"-16 UN thread, located inside the main hydraulic tank.

</div>Symptoms & Identification

A clogged hydraulic filter will give you clear signals that it's starving for fluid. This helps confirm you're diagnosing the right problem.

- Sluggish Performance: All hydraulic functions—boom lift, extension, swing—will feel slow, weak, and unresponsive.

- Jerky Movements: Instead of smooth operation, you'll notice a shudder or hesitation as the pump struggles to maintain consistent pressure.

- Whining Hydraulic Pump: A high-pitched whine from the pump area is a classic sign of cavitation. The pump isn't getting enough oil and is pulling in air, which is extremely damaging.

- Overheating System: The hydraulic oil temperature runs hotter than normal because the restricted flow can't be cooled effectively.

Ignoring these symptoms will quickly turn a simple filter swap into a catastrophic pump failure.

Tools Required

- Filter Wrench (Band or Socket Style)

- Metric Socket Set & Ratchet

- Clean Drain Pan (Large)

- Nitrile Gloves

- Safety Glasses

- Clean, Lint-Free Rags

Safety Warning

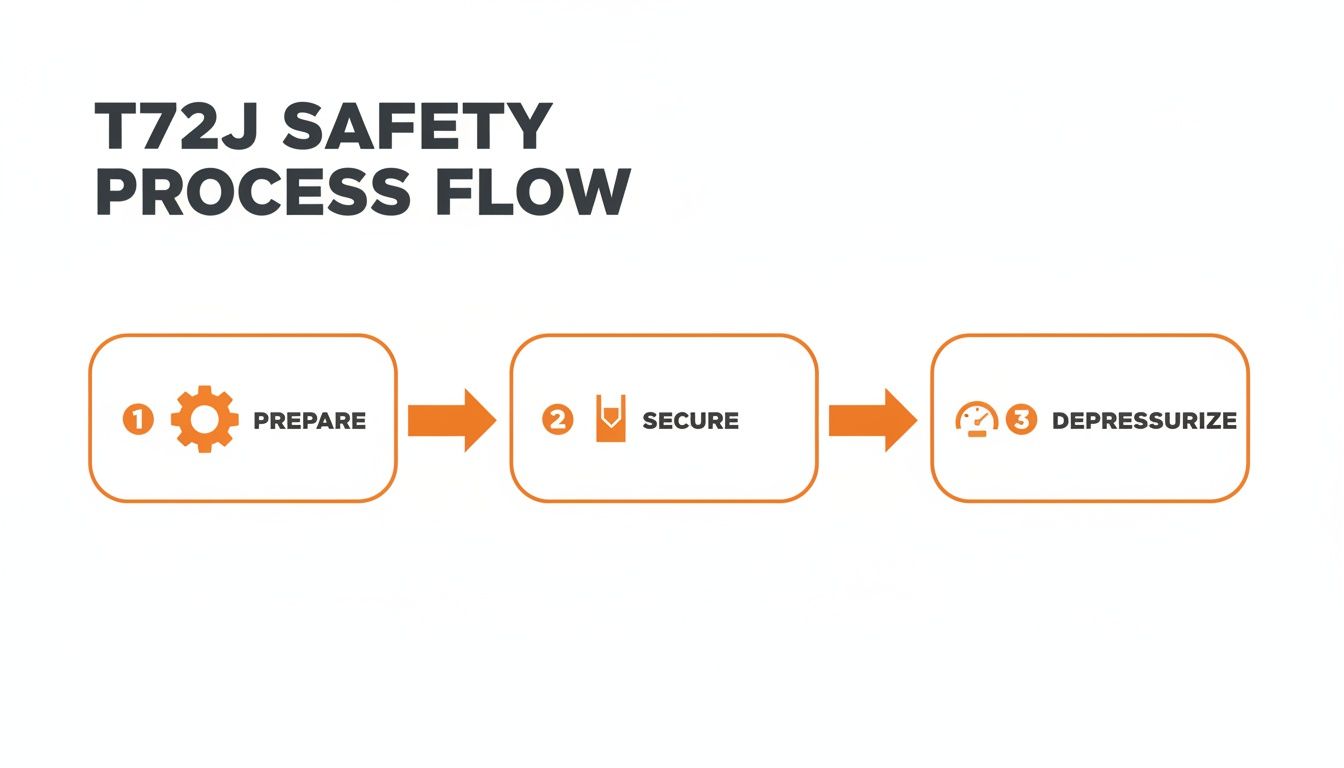

<div class="safety-warning"> **Safety Warning:** Stored hydraulic pressure is extremely dangerous. Fully lower the boom to the ground, shut down the engine, and cycle all hydraulic functions (lift, extend, swing) back and forth multiple times with the machine off to bleed off any residual pressure in the accumulators and lines. Chock the wheels to prevent rolling. </div>The Technical Guide (Step-by-Step)

This isn't a complex job, but working clean is critical to avoid introducing dirt into the system. The hydraulic tank is mounted on the chassis; you're looking for the rectangular service cover held on by several bolts.

Removing The Old Filter Element

- Clean the Area: Thoroughly wipe down the service cover and the area around it with a clean rag. This prevents debris from falling into the tank.

- Remove Cover Fasteners: Using the correct socket, remove the bolts holding the cover. Place them in a magnetic tray.

- Lift the Assembly: Carefully pull the service cover straight up. The filter element is attached to the underside and will be full of oil.

- Extract the Filter: Place the entire assembly in your drain pan. Use a filter wrench to break the old filter loose and unscrew it from the housing.

Installing The New Filter

Before installing, inspect the inside of the housing for metal shavings—a sign of a bigger problem like a failing pump.

- Prepare the New Filter: Dab a finger in clean hydraulic fluid and apply a thin film of oil to the new filter's gasket. This ensures a proper seal and prevents tearing.

- Install the New Element: Hand-tighten the new filter onto the housing until the gasket makes contact, then give it an additional three-quarters of a turn. Do not use a wrench to tighten it, as this can crush the canister.

- Reinstall the Assembly: Carefully lower the cover and new filter back into the tank. Ensure the cover gasket is clean and properly seated in its groove.

- Secure the Cover: Reinstall the cover bolts and tighten them in a crisscross pattern to ensure even pressure. Refer to your specific service manual for torque values—do not overtighten.

After the cover is secure, top off the hydraulic fluid to the correct level and start the machine. Check for any leaks around the service cover.

The Part You Need

Ordering the wrong filter guarantees downtime. These are the critical specs you must match for the LGMG T72J hydraulic return filter.

- Micron Rating: 10-micron nominal

- Thread Size: 1-1/2"-16 UN

- Gasket & Canister Dimensions: Must match the OEM part to ensure a proper fit inside the tank and a leak-proof seal.

Using a verified OEM-compatible filter is key. Downtime is the villain, and dealer lead times are brutal. China Lift Supply stocks this specific hydraulic filter in the US to avoid the 6-week dealer wait time.

Note: Components may vary by Gen 1 vs Gen 2 series. Verify with your parts manual.

Recommended Maintenance Intervals

The hydraulic filter isn't a "set it and forget it" part. Neglecting it allows contaminated fluid to destroy expensive pumps and valves.

- Inspect Every 250 Hours: Visually check the hydraulic fluid and filter element for signs of contamination (cloudy fluid, metal flakes).

- Replace Every 1,000-1,500 Hours: As a rule of thumb, replace the filter element in this range, regardless of appearance.

- Replace Immediately If: The filter media is damaged (torn or collapsed), the fluid is severely contaminated (milky with water), or the filter has been cleaned more than five times per LGMG guidelines.

You can find the full factory recommendations in the official T72J maintenance schedule. The cost of a filter is cheap insurance against a multi-thousand-dollar pump replacement. If your machine operates in a dusty or dirty environment, shorten these intervals significantly.

T72J Hydraulic Filter: FAQs

Can I use an aftermarket hydraulic filter?

Yes, provided it meets the critical specs: 10-micron rating, 1-1/2"-16 UN thread, and correct physical dimensions. A quality aftermarket filter provides identical performance without the dealer markup and 6-week lead time from overseas.

What happens if the filter goes into bypass mode?

When the filter is completely clogged, an internal bypass valve opens to prevent the pump from starving. However, this means it is sending unfiltered, contaminated oil directly to your most sensitive components. Running in bypass is an emergency that will rapidly cause catastrophic system failure.

What are the risks of delaying a filter change?

At first, you'll see poor performance. Silently, you are sandblasting the internals of your pumps and valves with microscopic contaminants. Every hour you run on a dirty filter turns a cheap maintenance job into a massive repair bill.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: LGMG T72J Hydraulic Filter at China Lift Supply.