If your Zoomlion lift is sluggish, whining, or unresponsive on a cold morning, your hydraulic oil is the problem. In freezing temperatures, the wrong fluid thickens into a useless gel, starving the pump and risking permanent damage. You need a high Viscosity Index (VI), low pour point fluid—specifically an ISO VG 32 grade designed for arctic conditions.

The Quick Diagnosis

That high-pitched screaming sound from your hydraulic pump on a frosty morning is cavitation. Your hydraulic oil has thickened into sludge, and the pump is sucking air. This will destroy your pump. The fix is to switch to an ISO VG 32 cold-weather hydraulic fluid with a pour point below -35°C (-31°F).

Symptoms & Identification

If your Zoomlion is showing these signs on a frosty morning, the oil is the problem:

- A loud whining or grinding noise from the hydraulic pump during a cold start.

- Sluggish, jerky, or delayed hydraulic functions (lift, drive, steer).

- The machine feels weak or slow, even at full throttle.

Tools Required

- Large Drain Pan (sized for your machine's tank capacity)

- Filter Wrench (strap or chain style)

- Socket Set and Wrenches

- Torque Wrench

- Clean Funnels

- Shop Rags

Safety Warning

Chock wheels and lower all attachments to the ground before starting. Relieve all hydraulic system pressure by cycling the controls several times with the machine off. Fluid under pressure can penetrate skin and cause severe injury.

The Technical Guide: Choosing the Right Fluid

Using the wrong fluid isn't just about poor performance; it's a fast track to burning out your main hydraulic pump, a costly and time-consuming repair. Standard hydraulic oils (like ISO VG 46 or 68) simply aren't formulated for extreme temperature swings. Their viscosity skyrockets as the temperature drops, creating immediate problems.

- Pump Starvation (Cavitation): The pump spins faster than it can suck in the thick, molasses-like oil. This creates tiny vapor pockets that collapse violently, causing that distinct whining noise and chipping away at internal pump components.

- Increased System Pressure: The thickened oil struggles to move through hoses and valves, putting immense strain on the entire system and leading to blown seals.

- Delayed Function Response: Every hydraulic action will be slow and jerky because the fluid is too thick to transmit pressure efficiently.

Decoding the Specs You Actually Need

When you're staring at a spec sheet, it’s easy to get lost. For keeping your Zoomlion running in the cold, only a few numbers matter.

- ISO Viscosity Grade (VG): This is a measure of the oil's thickness at 40°C (104°F). For nearly all modern Zoomlion equipment in cold weather, ISO VG 32 is the spec. Anything heavier is a direct path to pump failure.

- Viscosity Index (VI): This is the most important spec. It tells you how much the oil's thickness changes with temperature. A VI of 150 or higher is non-negotiable. This high rating means the oil resists turning to sludge in the cold and won't thin out to water when the machine warms up.

- Pour Point: This is the lowest temperature at which the oil will still flow. You need a pour point well below the coldest temperature you expect to work in. A good cold-weather oil for a Zoomlion will have a pour point of at least -39°C (-38°F) or lower.

Early 2010s manuals might have vaguely suggested engine oils, but by 2020, the factory specs for modern ZA-series lifts standardized on ISO 32 with a VI of 150. This change was a direct response to field issues where oil viscosity surged below freezing. You can review older Zoomlion maintenance documents for context to see this progression.

If you're already running into these issues, our guide on advanced Zoomlion troubleshooting steps can help, but always start by confirming you have the right fluid in the tank.

Step-by-Step: Cold Weather Hydraulic Fluid Change

Switching to the right oil is a full system flush. You need to get the old, thick fluid out and the new fluid in without introducing contaminants.

- Warm Up the Machine: If possible, run the machine for 5-10 minutes at low idle. This warms the existing oil just enough to help it drain faster.

- Position and Drain: Park on a level surface. Locate the hydraulic tank drain plug, clean the area around it, place your drain pan underneath, and remove the plug. Let the old fluid drain completely.

- Replace the Hydraulic Filter: This is non-negotiable. Locate the filter, place a pan under it, and remove it with a filter wrench. Lightly coat the rubber gasket on the new filter with new hydraulic fluid. Install the new filter by hand until the gasket makes contact, then tighten another three-quarters of a turn. Do not overtighten.

- Refill with Correct Fluid: Using a clean funnel, pour in the new ISO VG 32 high-VI hydraulic oil. Fill to the "full" line on the sight glass or dipstick. Note: Components may vary by Gen 1 vs Gen 2 series. Verify capacity with your parts manual.

- Purge Air from the System: With the engine at low idle, slowly cycle every hydraulic function through its full range of motion several times. This is crucial for pushing trapped air out of the cylinders and lines.

- Final Checks: Shut down and let the fluid settle. Check for leaks at the drain plug and new filter. Re-check the fluid level and top it off if needed. Torque the drain plug to the manufacturer’s specification. Refer to your specific service manual for torque values—do not overtighten.

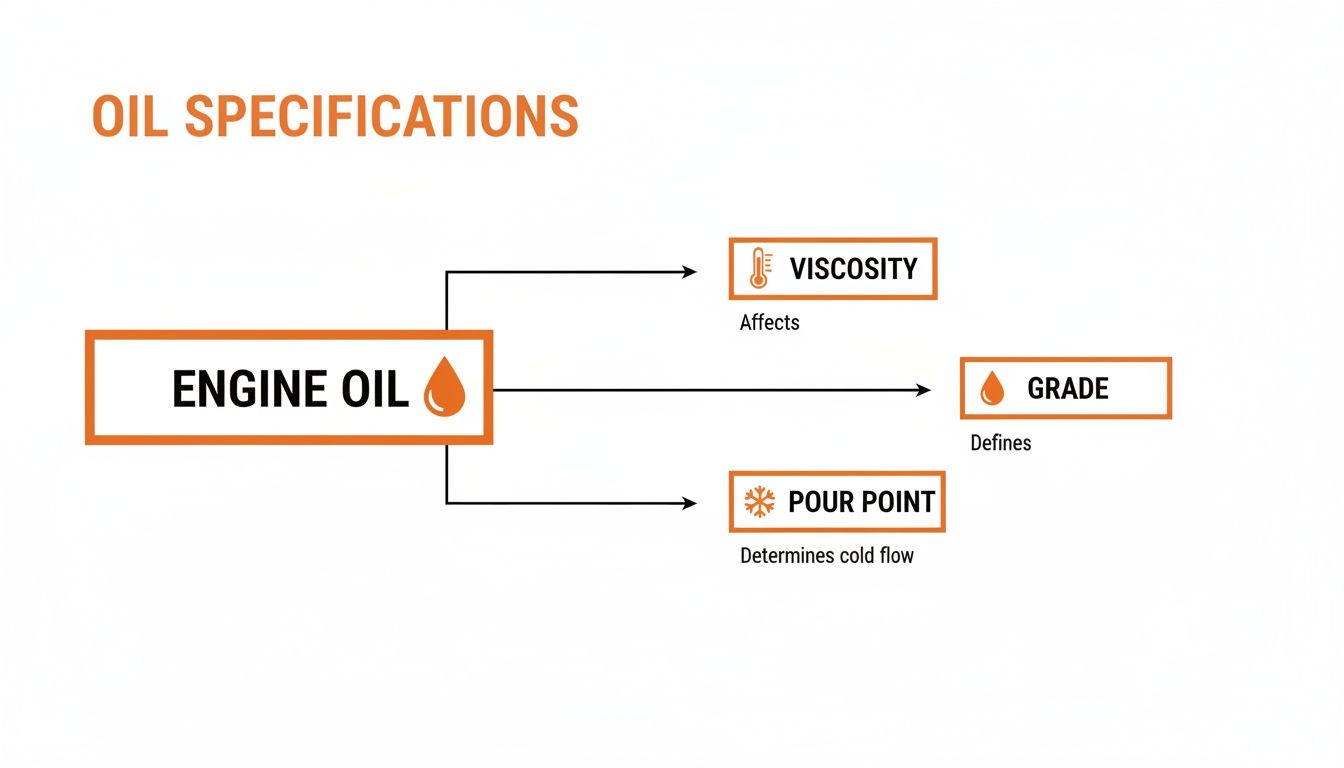

This diagram breaks down the essential oil specs—Grade, Viscosity, and Pour Point—that you absolutely must get right for cold weather performance.

The visual flow shows how each specification builds on the last, ensuring your fluid stays effective from a sub-zero startup all the way to full operating temperature. For more technical breakdowns, see our manufacturer resources and guides.

The visual flow shows how each specification builds on the last, ensuring your fluid stays effective from a sub-zero startup all the way to full operating temperature. For more technical breakdowns, see our manufacturer resources and guides.

Best Practices for Winter Operation

<iframe width="100%" style="aspect-ratio: 16 / 9;" src="https://www.youtube.com/embed/MKIBsDJF_3k" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>Pouring in the right oil is step one. How you start your Zoomlion on a freezing day is just as critical. The biggest mistake is firing up a cold-soaked machine and immediately trying to lift or drive at full speed. This puts an incredible shock load on the hydraulic pump before the fluid has circulated.

The Non-Negotiable Cold-Start Warm-Up

- Start the Engine: Let it idle at low RPM. Do not touch any hydraulic controls.

- Wait 5-10 Minutes: This allows the pump to circulate oil through the main lines, letting it warm up from the friction of circulation.

- Gentle Function Cycling: After the initial wait, slowly and smoothly cycle each hydraulic function one at a time through its full range of motion.

Daily Winter Pre-Operation Checks

Cold weather is brutal on components. Hoses become brittle, seals shrink, and water contamination can freeze solid. This daily check can catch problems before they become catastrophic failures.

| Check Item | Procedure/What to Look For | | :--- | :--- | | Hydraulic Hoses | Visually inspect all hoses for signs of cracking, brittleness, or stiffness. | | Fluid Level & Appearance | Check the sight glass. Fluid should be at the "full" mark and clear. A milky look indicates water contamination. | | Control Function Test | After warm-up, ensure all controls respond smoothly without hesitation. | | Listen for Leaks | With the machine running, listen for hissing sounds that could indicate a pinhole leak. |

The Part You Need

The real problem isn't just the cold; it's downtime. Waiting 6-8 weeks for a basic hydraulic filter from an OEM dealer is a non-starter when a project is on the line. The dealer network for many Chinese-made brands is still playing catch-up, meaning most parts are an ocean away.

China Lift Supply stocks the OEM-spec hydraulic filters you need right here in the US, ready for same-day shipping. While you grab the correct ISO VG 32 fluid locally, we can have the filter headed your way immediately, eliminating that long, costly wait.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: https://www.chinaliftsupply.com.