If your scissor lift is working on smooth, indoor concrete, polyurethane wheels are what you need. They handle a higher load and have less rolling resistance, making the machine more efficient. But for mixed-use sites, outdoor jobs, or any uneven ground where grip and vibration absorption are critical, rubber is the only choice. Knowing which is which prevents you from ordering the wrong part and causing more downtime.

The Quick Diagnosis

For smooth, indoor warehouse floors, you need polyurethane wheels for their high load capacity and low rolling resistance. For outdoor or rough terrain, you need rubber for its superior grip and shock absorption. The fastest way to tell them apart is the thumbnail test: polyurethane is rock-hard; rubber has a noticeable give.

Symptoms & Identification

Before you inspect the wheels, the operator's complaint will give you clues. A machine behaving poorly is a direct symptom of having the wrong wheels for the job.

- Machine feels sluggish or drains batteries fast: This points to rubber wheels being used on smooth concrete, causing high rolling resistance.

- Poor traction, especially on wet ramps or slight inclines: This is a classic symptom of polyurethane wheels, which get slick when wet.

- Black scuff marks on the floor: That’s rubber. Polyurethane is non-marking.

- A harsh, jarring ride: The operator is feeling every crack in the floor. That’s a polyurethane wheel transmitting every vibration to the chassis.

- "Chunking" or torn pieces on the wheel tread: You’re looking at rubber, which is softer and more prone to tearing on debris.

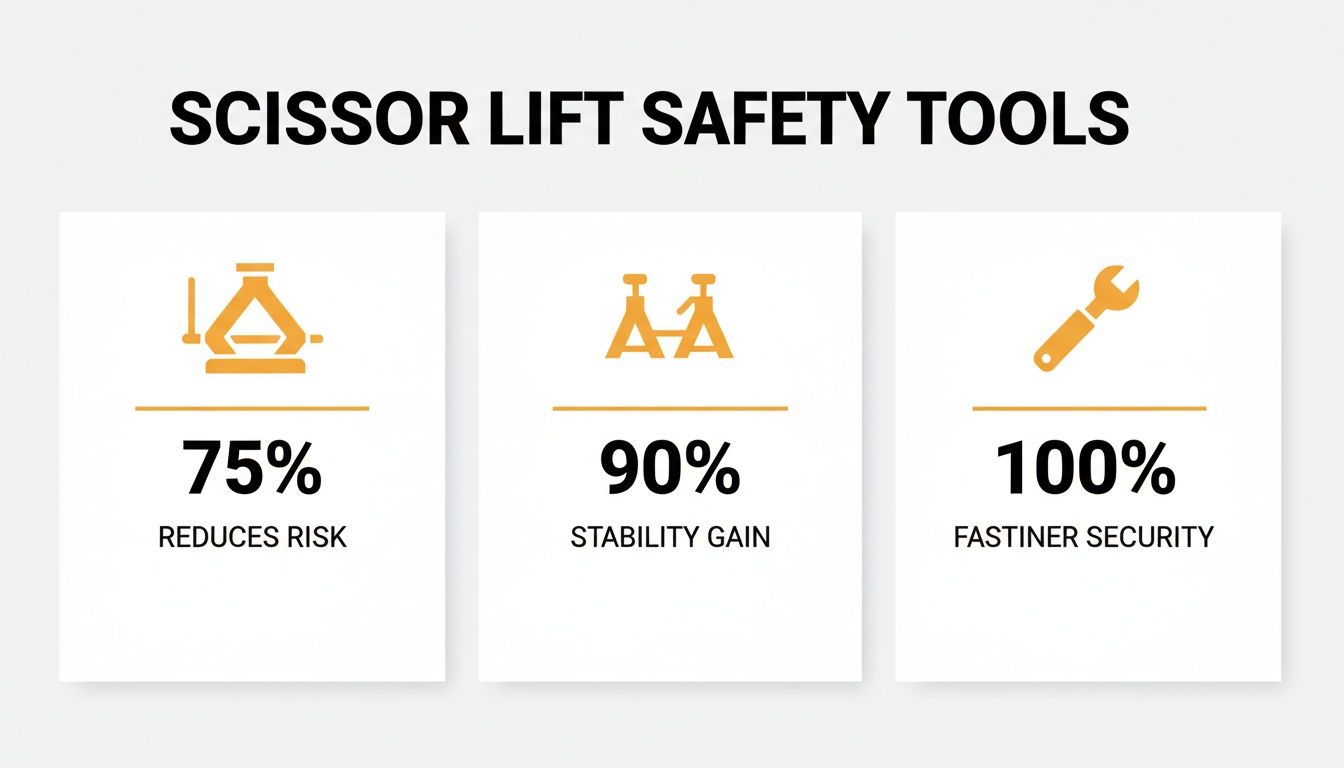

Tools Required

- Heavy-Duty Floor Jack (rated for the lift's weight)

- Certified Jack Stands

- Torque Wrench & Breaker Bar

- Correctly Sized Metric Sockets

Safety Warning

CRITICAL: Always support the scissor lift chassis with certified jack stands before removing any wheels. Never rely on the machine's hydraulics or a floor jack as the sole means of support. Power down the machine and remove the key to prevent accidental movement.

The Technical Guide: Field Identification

You don’t need a lab to identify the wheel material. These two physical checks will give you an answer on the shop floor in seconds.

-

Perform the Thumbnail Test. This is the fastest way to tell them apart. Press your thumbnail firmly into the wheel tread.

- Polyurethane: It will feel rock-hard, like pressing into solid plastic. You will get almost zero give. The material has a high durometer, typically 90-95 Shore A.

- Rubber: Your nail will sink in slightly. The material has a noticeable "give" or softness. It has a much lower durometer, around 65-75 Shore A.

- Pro Tip: If the wheel is dirty, scrape a small spot clean with a pocketknife to get a true feel for the material.

-

Inspect the Surface Finish and Markings. The look of the wheel is another dead giveaway.

- Polyurethane has a glossy, almost plastic-like sheen, even when worn.

- Rubber has a dull, matte finish that is non-reflective.

- Check for molded markings. Polyurethane wheels are sometimes stamped with "PU," while rubber tires often have size information molded into the sidewall like a car tire. You can cross-reference part numbers for specific scissor lifts using the machine's manual.

-

Consider the Environment. Where is the lift being used? The application is the biggest clue.

- Indoors on smooth concrete: Should be polyurethane for durability and efficiency.

- Outdoors, on rough surfaces, or on ramps: Must be rubber for traction and safety.

The Part You Need: Polyurethane vs. Rubber

Picking the wrong wheel causes premature wear, drains batteries, and creates unsafe operating conditions. This isn't personal preference; it's matching the wheel's engineering to the worksite.

Polyurethane: For Indoor Concrete

If your scissor lift operates exclusively on smooth, indoor concrete, polyurethane is the only correct choice.

- Load Capacity: Polyurethane handles 2-3 times the weight of rubber without deforming. A fully loaded Dingli JCPT2223DC demands this rigidity.

- Battery Efficiency: On electric lifts from LGMG or Sinoboom, polyurethane's low rolling resistance can reduce battery consumption by 15-20%. Rubber wheels create constant drag that drains batteries.

- Durability: It resists cuts and abrasions from metal shavings or shop debris that would tear rubber apart.

- Floor Protection: It's non-marking, which is critical for facilities with epoxy-coated or polished concrete floors.

Rubber: For Outdoor and Rough Surfaces

The moment you roll onto unprepared surfaces, polyurethane becomes a liability. For construction sites, gravel yards, or even indoor facilities with large expansion joints, rubber is mandatory.

- Traction: Rubber delivers up to 30% better grip on rough, dusty, or wet surfaces. Polyurethane becomes dangerously slick when wet. For a Sinoboom lift on a messy jobsite, that grip is non-negotiable.

- Shock Absorption: Rubber's elasticity dampens vibrations, protecting sensitive electronics like controllers and sensors from getting shaken to death. A polyurethane wheel transmits every jolt directly to the chassis, leading to mysterious electronic failures.

- Quieter Operation: Rubber is significantly quieter, making it better for noise-sensitive jobsites like hospitals or schools.

Why You Can't Mix Wheel Types

Never mix polyurethane and rubber wheels on the same lift. It creates an unstable platform because the rubber will compress more under load, causing the lift to sit unevenly. This puts uneven stress on the chassis and drive components, leading to premature motor or gearbox failure. If you need more help, check our other troubleshooting guides for common lift problems.

When replacing wheels, always tighten lug nuts to the manufacturer's specification using a calibrated torque wrench. If you do not have the manual, refer to your specific service manual for torque values—do not overtighten.

The Part You Need

Whether your Dingli needs polyurethane for indoor work or your LGMG needs rubber for a rough job site, waiting 6-8 weeks for a wheel from a dealer is not an option. That downtime is the biggest enemy of your uptime. China Lift Supply stocks both OEM-compatible polyurethane and rubber non-marking wheels in our US warehouse to avoid that 6-week dealer lead time. This means you get the right part with same-day shipping.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: [Link Placeholder].