Your Dingli lift is down, the boss is breathing down your neck, and the dealer just quoted you an 8-12 week lead time from China. That’s a non-starter. The real solution is finding a US-based supplier with in-stock, OEM-compatible parts ready to ship today. This guide is your shortcut to getting that machine earning its keep again—now, not two months from now.

The Quick Diagnosis The long wait for Dingli parts isn't about shipping; it's a symptom of a dealer network that doesn't stock components in the US due to high import tariffs and carrying costs. The fix is to bypass the dealer entirely and source a spec-for-spec compatible part from a US-based supplier who has the component physically on a shelf, ready for same-day shipping.

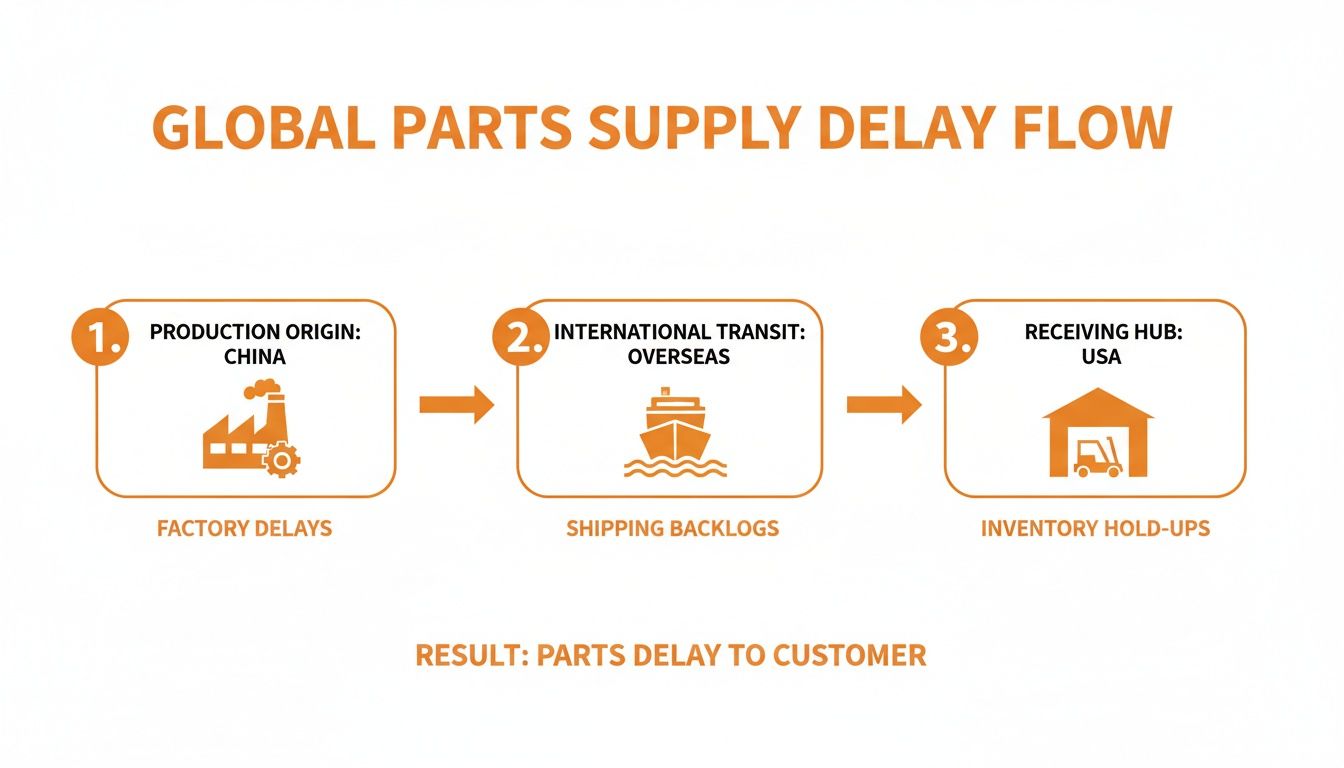

Symptoms of a Broken Supply Chain

You know the machine's symptoms, but what about the parts problem? Here’s what you see:

- Dealer quotes an 8-12 week lead time: This is the classic sign they don't have the part and must special order it from the factory in China.

- No one can identify the part: You send a photo to the dealer and get a shrug in response because the machine is a few years old.

- The price quote seems astronomical: Tariffs and international freight costs get passed directly to you.

- Your machine is down, and downtime is the enemy. Every hour that lift sits idle, it's burning a hole in the operation's pocket.

Bypassing the 8-Week Wait: The Technical Guide

The problem isn't the part itself—it's where the part is. Most dealers simply don't stock a deep inventory of Dingli components in North America. The carrying costs are high, and the demand for a specific sensor or valve is unpredictable, so they just don't bother. They place your order with the factory, and that’s what kicks off the painfully long international shipping process.

The villain here is Downtime caused by Dealer Lead Times. Sourcing hard-to-find Dingli parts in the USA requires a strategy that cuts the overseas supplier out of the immediate equation. The hero is a domestic supplier with parts physically on the shelf. This is where a dedicated US-based parts supplier like China Lift Supply completely changes the game. By stocking critical components right here, they compress the entire sourcing timeline from months to hours.

Here’s a quick breakdown of your options:

| Sourcing Method | Typical Lead Time | Part Availability | Cost Impact | | :--- | :--- | :--- | :--- | | OEM Dealer | 8-12 weeks | Low US stock | High due to downtime | | US-Based Supplier | 1-3 days | High in-stock inventory | Low, machine is back up |

The table makes it obvious. When the clock is ticking, there’s only one logical choice. This guide will walk you through the practical steps to nail down the exact component you need and get it from a US warehouse for immediate shipment. And if you get stuck on the technical side, our extensive library of Dingli troubleshooting guides can give you model-specific insights. Forget the supply chain excuses; it’s time to get your equipment running.

The Part You Need

The part you need is the one that's on a shelf in the USA. Relying on the dealer means getting stuck in a global logistics nightmare driven by economics and tariffs.

When your machine is down, understanding these forces is the first step to getting around them. The main villain here is the massive cost and risk dealers face when they import Chinese-made parts. They aren't just paying for the component; they're fighting a wall of duties and taxes that makes stocking anything but the most common filters a serious financial gamble.

The Tariff Triple Threat

Things got especially tough for dealers back in 2022. That’s when US authorities slammed Dingli's equipment with a colossal 43.49% anti-dumping duty, making direct imports incredibly expensive. This tariff was a sledgehammer to the supply chain. Jump to today, and new proposed tariffs on Chinese goods threaten to add another 34%, plus countervailing duties that tack on an extra 11.95%. When you run the numbers, the total landed cost for a part can balloon by over 50%. You can dive deeper into these economic pressures on Dingli's US operations to get the full picture.

This isn't just a political headline; it's the direct cause of your frustration. That 50% extra cost is why the dealer is hesitant to stock that specific hydraulic pump you need, forcing you into an 8-12 week lead time from the factory in China.

For you, the mechanic or fleet manager, this economic reality means one thing: unacceptable downtime. This is the core reason why sourcing hard-to-find Dingli parts in the USA requires a different approach.

The Dealer's Inventory Dilemma

Dealers move high-volume items. A specialized main control valve for a five-year-old Dingli JCPT1612DC scissor lift? That's a different calculation due to:

- High Carrying Costs: Stocking a part that might sit on a shelf for a year is expensive.

- Risk of Obsolescence: A part for a Gen 1 machine might not fit a Gen 2, leaving the dealer with a useless paperweight.

- Low Predictability: It's nearly impossible for a dealer to guess when a non-wear item like a platform control box will fail.

Because of this, the dealer’s default move is to special-order your part. This process has multiple stages, and each one adds more delay:

- Factory Production Lead Time: Your part might not even be built yet.

- Ocean Freight: The container ship journey alone takes weeks.

- Port Congestion & Customs: The part can sit at a US port for days or even weeks.

- Domestic Shipping: Finally, it's shipped from the port to the dealer, and only then to you.

This entire sequence is why a simple part replacement morphs into a two-month headache. The solution is finding a supplier who has already imported and stocked these components domestically. As you can see from our shipping policy, having parts already on US soil changes the entire delivery timeline.

Nailing The Part Number Without The Manual

The parts manual is gone. The tag on the component is worn smooth. It’s a classic Tuesday afternoon in any service shop. This isn't a dead end; it's where the real detective work begins.

The Technical Guide (Step-by-Step Identification)

- Treat it like a crime scene. Get out your phone and take clear, high-resolution photos from multiple angles:

- Straight-on shot: Captures the overall shape and size.

- Profile view: Shows mounting points and depth.

- Connector close-up: This is non-negotiable for electrical parts. Get a clear shot of the pin configuration.

- Port locations: For a hydraulic valve or pump, you need a picture of every inlet and outlet.

- Hunt For Manufacturer Stamps. Dingli doesn't build every component. They source from global industrial giants. Wipe down the component and look for names like 'Danfoss' on a hydraulic valve, 'Curtis' on a controller, or 'HydraForce' on a solenoid coil. Finding this brand name gives you a new search path to cross-reference the part. The original manufacturer's part number is gold.

- Leverage The Quick Part Finder. Sitting on a bucket, endlessly scrolling through generic parts catalogs, is a waste of time. Tools like the China Lift Supply Quick Part Finder were designed for this exact scenario. Instead of hunting for a part number you don't have, you can work backward. Filter by your machine's make (Dingli), type (e.g., Scissor Lift), and model (e.g., JCPT1612DC). This instantly narrows the field from thousands of parts down to a manageable list.

- When All Else Fails, Measure Twice. Break out the calipers. For mechanical or hydraulic parts, precise measurements are your final confirmation.

- Mounting Holes: Measure the center-to-center distance of the bolt holes.

- Shaft Diameter: For a motor or pump, get an exact diameter.

- Hydraulic Fittings: Identify the thread type and size (e.g., JIC, ORB).

Pro Tip: Compare your photos and measurements to the high-resolution images on the supplier's website. If the ports on a valve look different or a mounting tab is in the wrong spot, it's the wrong part. This five-minute check saves you the massive headache of a return.

As you can see, the delay isn't just shipping time. Bypassing this slow, traditional supply chain is everything.

OEM vs. OEM-Compatible: A Shop Floor Perspective

Let's get straight to the point. When you have a Dingli lift down, the logo on the box is the last thing you should be worrying about. The only question that matters is: does the part meet the machine's exact engineering specifications?

<iframe width="100%" style="aspect-ratio: 16 / 9;" src="https://www.youtube.com/embed/AXUcw297sS4" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>Think about the components on your lift—joysticks, contactors, hydraulic filters. The "OEM" version is often a rebranded component from a major global manufacturer. Dingli doesn't forge its own hydraulic pumps; they source them from industry leaders like HydraForce, Bosch Rexroth, or Delta-Q.

When you buy an "OEM" part, you're often just paying a premium for a Dingli sticker on a box that contains a standard industrial part. A smart, US-based supplier cuts out that middle step. They go directly to the original source or find a perfect equivalent that matches the specs one-for-one.

Why Specs Always Trump Branding

The brand is irrelevant; the data is everything. A replacement part must be an exact functional match. Anything less is a gamble. A reliable supplier isn’t just moving boxes—they're verifying compatibility.

This means checking key performance metrics are identical:

- Pressure Ratings: A hydraulic valve must handle the system's PSI.

- Voltage and Amperage: The wrong electrical specs can fry a controller or wiring harness.

- Flow Rates (GPM): A mismatched flow rate can make a function dangerously fast or frustratingly slow.

- Connectors and Fittings: The part must physically plug into the machine’s existing harness and hydraulic lines without rigging.

This level of verification is what separates a true parts partner from a random online seller. When you're sourcing hard-to-find Dingli parts in the USA, your supplier must do this homework for you.

The goal isn't just to fix the machine; it's to restore it to its original performance and safety standards. An OEM-compatible part that meets or exceeds the original specs does this just as effectively as the dealer's part—but without the crippling lead time.

Building a More Resilient Supply Chain

Here's the hard truth: relying solely on the OEM dealer makes your entire operation fragile. You're tethering your uptime to a slow supply chain vulnerable to tariffs, port congestion, and factory backlogs in China.

By partnering with a US-based supplier like China Lift Supply, you're building a more robust supply chain for your fleet. You gain access to a network of verified, in-stock components that are already sitting on a shelf on this side of the ocean. This crushes downtime, keeps your projects on schedule, and directly impacts your bottom line.

The machine is back to making you money. Period.

Fleet Programs & Net 30 Terms: The Pro's Toolkit

When you're managing a whole fleet, sourcing parts is about maintaining operational readiness. One machine down is a headache; ten machines down is a five-alarm fire. Shifting from reactive purchases to a structured partnership with your parts supplier pays off big time.

For fleet managers and rental houses, Fleet Accounts and Net 30 payment terms aren't just perks. They are essential business tools that impact cash flow and simplify procurement.

From Emergency Purchase To Strategic Sourcing

Picture this: a huge job is about to kick off, and you discover half your Dingli scissor lifts have failing chargers. Placing ten separate online orders is an administrative nightmare. A Fleet Program cuts through that chaos by consolidating your purchasing, often unlocking preferred pricing and dedicated support. Instead of typing in payment info for every order, a fleet account keeps your details on file. This saves hours, slashes errors, and gets your parts on a truck faster.

This isn't just about convenience. In an industry where giants manage massive fleets and scissor lifts drive huge rental revenue, efficient parts management is a sharp competitive edge. Delays aren't an option.

As Chinese OEMs like Dingli push for a larger global market share, the need for agile, US-based parts sourcing becomes critical. Building a supplier relationship is a strategic move to insulate your operation from international supply chain meltdowns.

Improve Your Cash Flow With Net 30 Terms

Having to pay upfront for every hydraulic pump or controller ties up capital. Net 30 terms are a powerful tool for improving cash flow. You get the part you need now but don't have to pay for it for 30 days. This gives your business critical breathing room and allows you to align parts expenses with your revenue cycle.

Getting qualified is usually straightforward for established businesses:

- Business Verification: Confirm you're a legitimate rental fleet, reseller, or large-scale operation.

- Credit Application: A simple application to get your account established.

- Purchase History: A consistent ordering history builds the trust needed to extend credit.

By establishing Net 30 terms with a US supplier like China Lift Supply, you create a financial buffer that helps you navigate market challenges without sacrificing speed. You can read more about the global AWP market dynamics and Dingli's position to understand the bigger picture. These programs transform your parts supplier from a vendor into a strategic partner.

Get Your Dingli Part Shipped Today

Here’s the bottom line: your machine is down, and every hour it sits idle is costing you money. You can call the dealer and maybe see that part in eight weeks. Or, you can get the right part on a truck this afternoon from a US-based warehouse.

By working with a supplier like China Lift Supply that has a physical US warehouse, you completely sidestep international shipping delays and customs headaches.

The Real Cost of Waiting

Downtime can cost an average of $1,500 per hour for an idle machine. That's a catastrophic number that kills job profitability.

The choice is simple: wait for the dealer and let the costs pile up, or solve the problem right now. Your boss, your customer, and your schedule will thank you.

A domestic supplier with a US hub stocks common Dingli-compatible wear items, electrical components, and drive motors, offering same-day shipping. You get the part in a couple of days. That’s the difference between a minor hiccup and a major financial loss. You can find hundreds of in-stock Dingli parts ready for immediate shipment and stop the bleeding.

Questions We Hear All the Time About Dingli Parts

Here are the straight-up answers to the most common questions we get from mechanics trying to get a Dingli lift back on the job.

Can I Use an Aftermarket Part Without Voiding My Warranty?

Using a high-quality aftermarket part that meets or exceeds the original's specifications will almost never void your machine's warranty. The crucial term here is "spec-for-spec." As long as the replacement part didn't cause the failure, your warranty should still protect you. A good supplier is obsessed with making sure pressure ratings, voltage, and dimensions are an exact match.

How Can I Be Sure a Compatible Part Will Actually Fit?

Trust, but verify. A parts partner worth their salt will give you high-resolution photos, precise measurements, and detailed specs. Before you buy, do this three-step check:

- Compare the Photos: Put the picture of your old part side-by-side with the new one. Scrutinize every mounting hole and connector.

- Grab the Calipers: If measurements are provided, confirm critical dimensions.

- Check the Fitment List: Make sure your exact Dingli model is specifically listed as a fit.

This five-minute sanity check can save you days of headache. Note: Components may vary by Gen 1 vs Gen 2 series. Verify with your parts manual if unsure.

What’s a Realistic Shipping Time in the USA?

If a supplier has the part on a shelf in a U.S. warehouse, expect standard ground shipping to take 1-5 business days. For urgent jobs, most reputable suppliers offer options like Next Day Air. The magic phrase is "In Stock in the USA." If you see "Ships from Manufacturer," you're probably looking at the same 8-12 week boat ride.

Do I Need a Special Account to Buy Parts?

Not for a one-off purchase. But if you’re running a rental house or a large fleet, setting up a business account is a no-brainer. This is your ticket to perks like Fleet Program pricing and Net 30 payment terms. It makes future orders faster and helps your cash flow. Taking a few minutes to get an account set up is one of the smartest things you can do to prepare for the next breakdown.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: https://www.chinaliftsupply.com.