The Quick Diagnosis: If your Sinoboom is throwing multiple unrelated error codes, functions work from the ground but not the platform (or vice-versa), or the tilt alarm screams on level ground, your platform control box has an internal failure. The fix is a replacement, not a repair.

Symptoms & Identification

A failing platform control box doesn't just throw one clean fault code. It causes system-wide chaos. Your operator will report confusing, intermittent problems that seem to change by the minute. This is your biggest clue.

- Multiple, Unrelated Fault Codes: You'll see errors for a lift solenoid, a tilt sensor, and a joystick all at once. This isn't three parts failing; it's the control box processor getting scrambled.

- Asymmetrical Function: The lift works perfectly from the ground controls, but the platform controls are dead, or vice versa. This indicates a CAN-Bus communication failure originating in the box.

- Phantom Tilt Alarms: The tilt alarm goes off constantly, even when the machine is parked on flat concrete. The internal inclinometer on the circuit board is failing.

- Unresponsive or Laggy Controls: The operator moves the joystick, but the machine hesitates, stutters, or doesn't respond at all. The input signal is getting lost inside the control box.

- Erratic Overload Warnings: The basket overload alarm might trigger with an empty platform or fail to go off when genuinely overloaded. The controller is misinterpreting the load cell signal.

Tools Required

- High-quality Multimeter (with sharp probes)

- Metric Socket and Wrench Set

- Terminal Cleaning Brush Kit

- Dielectric Grease

- Laptop with Sinoboom Diagnostic Software (for calibration of new box)

Safety Warning

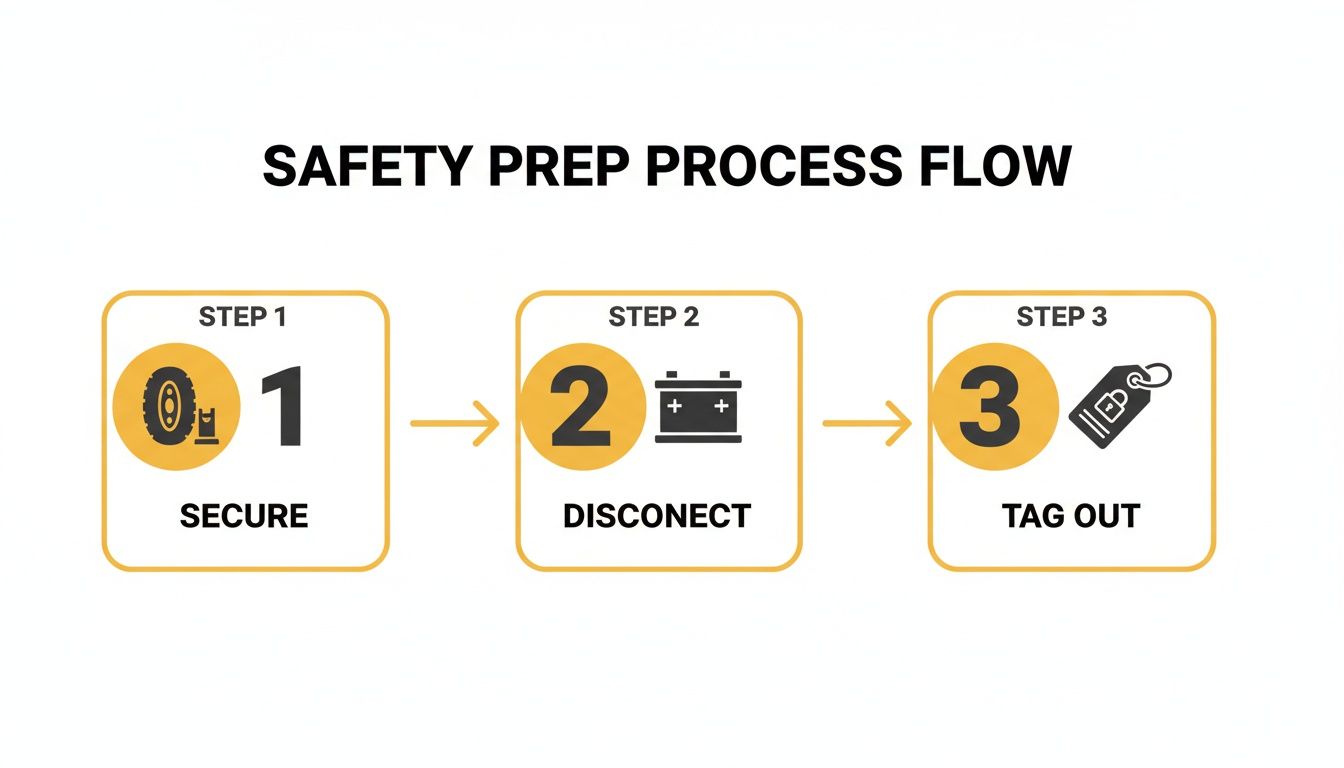

Disconnect the main battery negative terminal before you unplug any connector from the control box. Failure to do so can send a voltage spike through the ECU, turning a repairable issue into a completely fried module. Chock the wheels and lock out/tag out the machine before starting any work.

The Technical Guide (Step-by-Step)

Follow this logical path to confirm the control box is toast before you order a new one. Don't skip steps.

-

Perform a Visual Inspection. Your eyes are your first tool. Check the control box housing for cracks or damage. Inspect every wire harness and connector for chafing, pinched wires, or the green crust of corrosion. Gently tug on the connectors to check for loose pins.

-

Verify Power and Ground. Set your multimeter to DC Volts. With the key on, back-probe the main power and ground pins on the primary connector going into the control box. You must see a stable system voltage (e.g., 24V or 48V). If voltage is low or fluctuating, the problem is upstream. If voltage is good, confirm you have a clean, solid ground. A bad ground causes all kinds of phantom electrical gremlins.

-

Isolate Inputs. If power and ground are solid, test a single input. For example, have an assistant move the joystick while you check the signal voltage at the pin entering the control box. If you have a good signal from the joystick but the box produces no output (no click from a solenoid, no voltage sent to a function), you've confirmed the signal is dying inside the box.

-

Check CAN-Bus Communication. Most Sinoboom control modules have small LEDs that indicate CAN-Bus health. A steady, rhythmic flash usually means communication is good. A solid light, no light, or an erratic flash points to a communication failure, which often originates in a faulty control box processor. If you have good power, ground, and inputs, but the box is dead or outputs are non-existent, the unit has failed internally.

The Part You Need

Once diagnosed, the only fix is replacement. The circuit boards are potted in epoxy, making component-level repair impossible. Waiting for a control box from the dealer can mean 6-8 weeks of downtime while the part ships from overseas.

China Lift Supply stocks OEM-compatible Sinoboom platform control boxes in the US to avoid the 6-week dealer lead time.

Note: Components may vary by Gen 1 vs Gen 2 series. Verify the part number with your machine's serial number and parts manual before ordering.

Why Did My Control Box Fail?

A control box rarely dies on its own. Something killed it. Identify the root cause before you install a new one.

- Water Ingress: This is the #1 killer. Aggressive pressure washing forces moisture past the seals, corroding the circuit board. If you open the old box and see a white or greenish crust, that's your smoking gun.

- Voltage Spikes & Vibration: Improper jump-starting or welding on the chassis without disconnecting the electronics will fry the box instantly. Years of job-site vibration can also cause microscopic cracks in solder joints, leading to intermittent failures.

- External Wiring Faults: A corroded harness connector or a shorted solenoid can send bad signals back to the box, stressing and eventually destroying the internal components. Always inspect the entire circuit, not just the box.

After Installation: Calibration is Mandatory

You cannot skip this step. After installing the new control box, you must connect a laptop with the proper diagnostic software and perform a full machine calibration. The new box is a blank slate; it needs to be "taught" the correct parameters for drive speed, steering limits, and lift/lower functions for your specific machine. Skipping calibration will result in jerky, unpredictable, and unsafe operation.

For more diagnostic help, check our other Sinoboom troubleshooting guides and mechanic resources. You can also reference the official Sinoboom operator's manual for model-specific info. We carry a full line of Sinoboom lift parts.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: https://www.chinaliftsupply.com.