If your Sinoboom scissor lift is completely dead when you plug it in—no lights, no hum, nothing—the main charger fuse is your number one suspect. This guide will walk you through the diagnosis and fix to get you back online fast.

The Quick Diagnosis A completely dead charger (no lights) and no audible "click" from the main contactor when plugging in the machine points directly to a blown primary charger fuse. The fuse sacrificed itself due to a power surge, a bad extension cord, or a short.

Symptoms & Identification

Before tearing into the machine, confirm you're seeing these classic signs of a blown main charger fuse:

- Charger is completely dead: No lights illuminate on the charger unit when plugged into a known-good outlet.

- No "click" sound: You do not hear the main contactor engage when AC power is connected.

- BMS or display is blank/faulted: The machine's battery display may be off or show a critical charging system error.

This combination separates a simple fuse issue from a more complex problem like a failed charger unit or a bad battery pack.

Tools Required

- Multimeter: Must have a continuity setting (the one that beeps).

- Basic Socket Set: A 1/4" or 3/8" drive set for panel covers.

- Insulated Screwdrivers: A non-negotiable safety item.

- Headlamp: Fuse panels are always buried in dark, awkward spots.

- Fuse Puller or Needle-Nose Pliers: To safely remove the fuse.

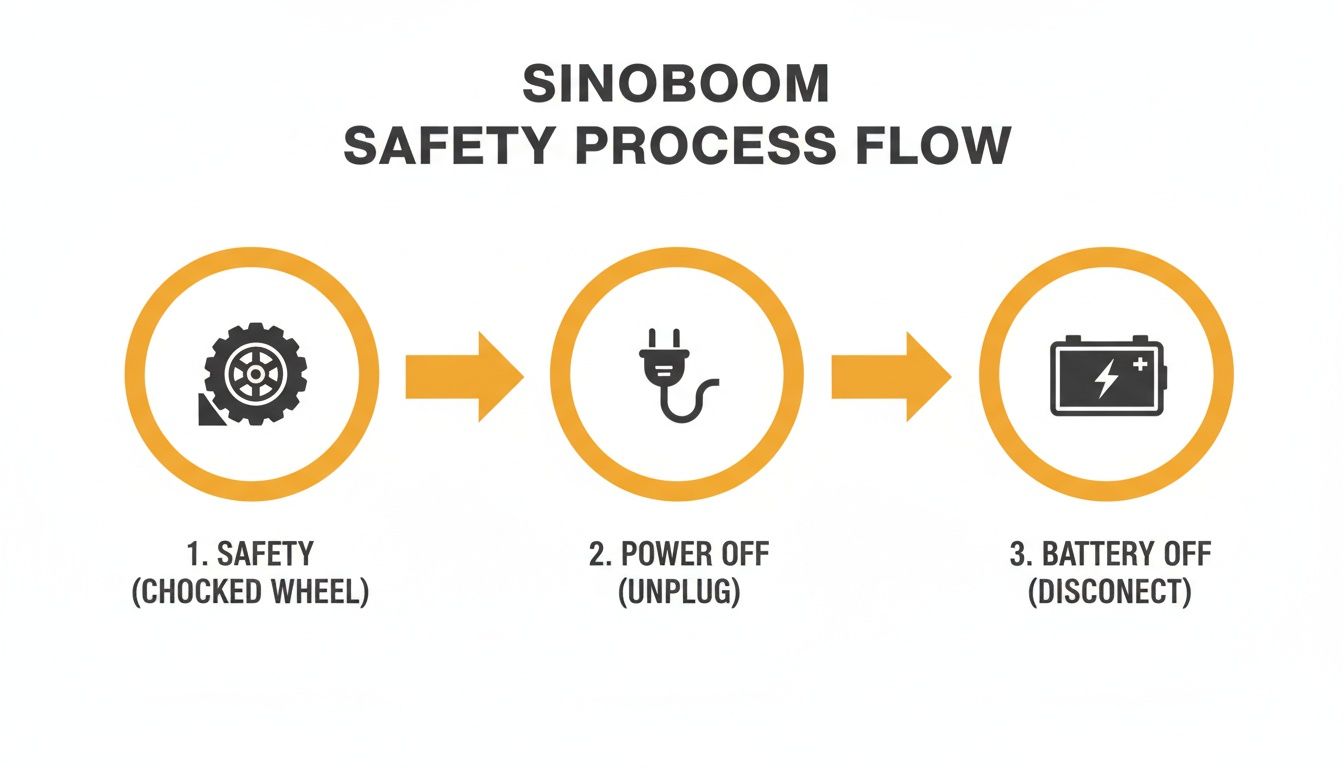

Safety Warning

CRITICAL WARNING: Always disconnect the main negative battery terminal AND unplug the machine from any AC power source before you open an electrical panel. The charging circuit can hold a nasty residual charge. Skipping this can lead to severe electrical shock or instantly fry expensive components. Chock the wheels to prevent movement.

The Technical Guide: Locating, Testing, and Replacing the Fuse

Step 1: Locate the Main Fuse Panel

On most common Sinoboom models like the 1932ME or the 2746E, the main fuse panel is located in the chassis battery compartment. You may need to move a battery cable to access the cover. Open the panel and look past the smaller automotive-style fuses.

Step 2: Identify the Charger Fuse

You are looking for a larger blade or cartridge-style fuse. It is typically labeled 'Charger' or will have a high amperage rating like 30A or 36A stamped directly on it. This is the main line of defense for the entire charging system.

Step 3: Remove the Fuse

Using a fuse puller or needle-nose pliers, carefully pull the fuse straight out of its slot. Do not wiggle it excessively, as this can damage the fuse block terminals.

Step 4: Test the Fuse with a Multimeter

Set your multimeter to the continuity setting (it has a symbol like a sound wave). Touch the probes together to confirm you hear a beep.

- Touch one probe to each metal blade on the fuse.

- A solid, continuous beep means the fuse is good. The electrical path is intact. Your problem lies elsewhere.

- Silence means the fuse is blown. The internal filament is broken. You have found the problem.

A visual check is also effective. A snapped or burnt-looking metal strip inside the fuse confirms it's dead.

Sinoboom Charger Fuse Diagnosis

| Test Method | Good Fuse Reading/Observation | Blown Fuse Reading/Observation (Needs Replacement) | | :--- | :--- | :--- | | Multimeter Test | Continuous beep on the continuity setting. | Silence. No beep, indicating an open circuit. | | Visual Inspection | The internal metal filament is intact and unbroken. | The filament is visibly broken, snapped, or has a dark burn mark. |

Step 5: Identify the Root Cause

Before installing a new fuse, determine why the old one blew. The number one cause is using a long, underrated extension cord (less than 12-gauge). This causes a voltage drop, forcing the charger to pull more amps and pop the fuse. Other causes include:

- Power surges from the job site's grid or generator power.

- A frayed or damaged machine power cord creating a short.

- An internal fault developing within the charger itself.

Step 6: Install the New Fuse

Install a new fuse with the exact same amperage rating. Never use a higher-rated fuse, as this removes circuit protection and can cause a fire or destroy the charger and control module. Once the new fuse is installed, reconnect the battery and plug the machine in to test.

For more advanced diagnostics, check out our comprehensive Sinoboom troubleshooting guides.

The Part You Need

For most Sinoboom scissor lifts, you’ll need a standard 30A or 36A automotive-style blade fuse. Calling the dealer often means a 6-8 week lead time from the factory in China for a simple fuse, which is a non-starter for a machine that needs to be working tomorrow.

China Lift Supply stocks these common, high-failure-rate fuses and other Sinoboom electrical parts in our Kansas warehouse. They are OEM-compatible and ready for same-day shipping, so you can fix the problem in days, not months. This avoids the dealer lead time and gets your equipment back on the job.

We also stock a full line of OEM-compatible Sinoboom chargers for cases where the charger unit itself has failed. Learn more about the technology in Sinoboom electric scissor lifts on Rentalex.com. This is common for popular models like the 2746E and 3346E.

Note: Components may vary by Gen 1 vs Gen 2 series. Verify with your parts manual.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: https://www.chinaliftsupply.com.