If your charger is dead, the quick answer is yes, you can often swap a Sinoboom and a Zoomlion charger, but only if you match the specs. Most of their electric scissor lifts use a 24V/30A system for lead-acid batteries. The trick is verifying the voltage, amperage, and connector pinout are identical. Using the wrong charger will fry a new set of batteries or damage the lift's controller.

<div class="feature-box"> <h3>The Quick Diagnosis</h3> <p>Yes, you can swap them, provided you match specs. The likely cause for a dead charger isn't the charger itself, but often a faulty interlock circuit or a dead battery pack. If you need a replacement, the part you need is a universal <strong>24V/30A</strong> charger that has been verified for both brands to avoid the 6-week dealer lead time.</p> </div>Symptoms & Identification

Before you blame the charger, confirm the machine is showing one of these classic signs of a charger or battery system failure. This helps confirm you're troubleshooting the right problem.

- Charger status light flashes a Red-Green-Red pattern: This often indicates the battery pack is too deeply discharged for the charger to recognize it.

- No lights or fan activity on the charger when plugged in: Assuming you have confirmed AC power at the outlet, this points to a failed internal power supply or main control board on the charger.

- Machine dies almost immediately after unplugging: The charger may appear to work, but it's only providing a "surface charge," indicating a failing charger or a sulfated battery pack that can't hold a charge.

- The machine's controller shows a low voltage code even after an overnight charge.

Tools Required

- Multimeter (for voltage and continuity checks)

- Socket set and wrenches (for removing and installing the charger)

- Battery Load Tester

Safety Warning

Disconnect the main negative battery terminal before starting any work. Chargers and battery packs contain high-amperage DC power. Shorting a terminal can cause severe burns, arc flashes, and equipment damage. Verify the machine is locked out and tagged out.

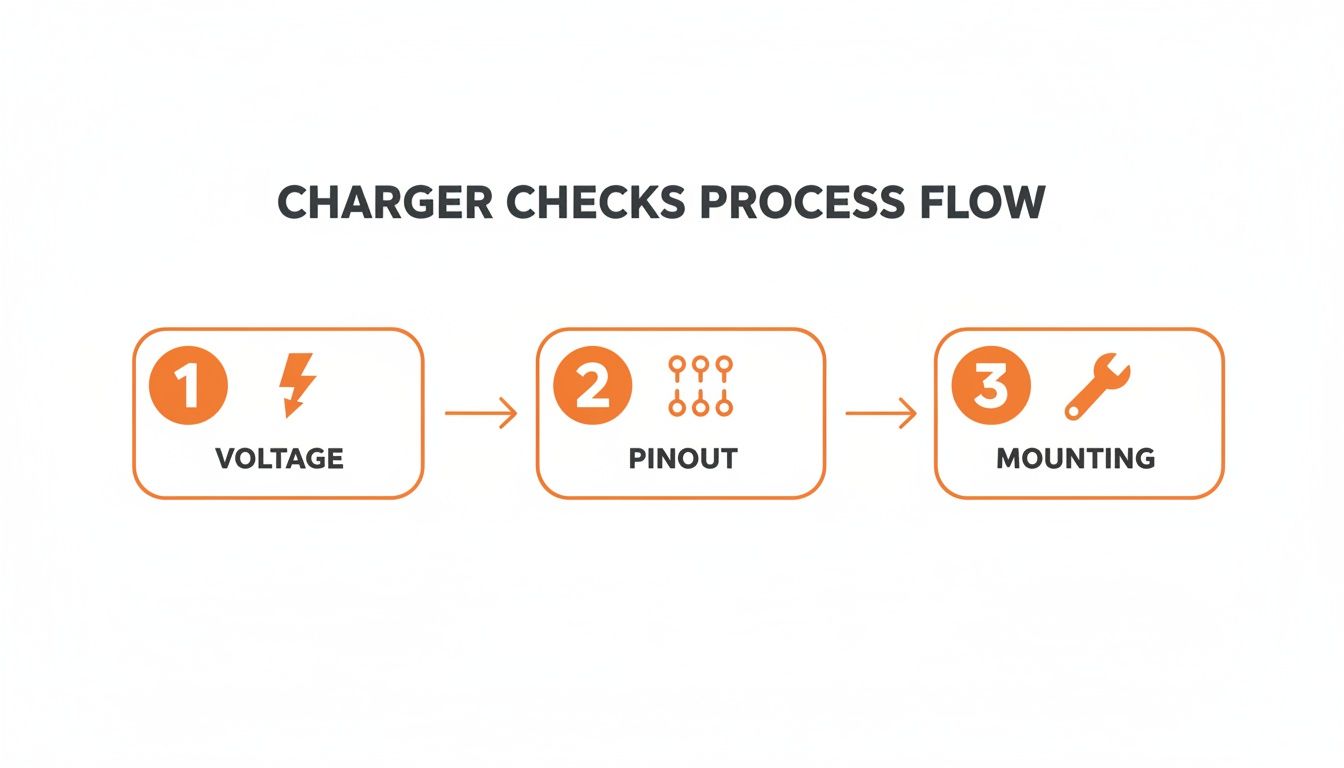

The Technical Guide: Verifying Interchangeability

A successful charger swap is more than just matching plugs. Get it wrong, and you can cook a $2,000 battery pack or even fry the machine's controller. Follow this step-by-step process.

1. Match Voltage and Amperage

This is the first and most fundamental check. It's completely non-negotiable.

The vast majority of Sinoboom and Zoomlion electric scissor lifts run on a 24V nominal system. That means their chargers must have an output of 24V with an amperage rating between 25A and 30A.

- Action: Inspect the data plate on the original charger and confirm the DC Output. It must match the replacement.

- Voltage: Using a charger with higher voltage (e.g., 36V) will cause catastrophic damage.

- Amperage: Amperage is charging speed. You can use a slightly lower amperage charger in a pinch, but it will significantly extend charge times. Stick to the factory-spec 25A-30A range for battery health.

Shop Talk: Think of it like this: Voltage is the pressure of the electricity, and amperage is the flow. You absolutely need the correct pressure (24V) to fill the batteries, and the right flow (30A) to do it efficiently without overheating them.

2. Verify Connector Pinout with a Multimeter

Just because the plug fits doesn't mean it's wired correctly. Both brands often use Anderson SB style connectors, but the pinout—which pin does what—can vary. You must verify the positive, negative, and interlock pins.

- Action: Set your multimeter to DC Volts. Connect the black probe to a clean chassis ground. Use the red probe to test each pin on the machine-side connector.

- The pin that reads ~24V is your Positive (+).

- The pin that shows continuity to the chassis is your Negative (-).

- The remaining pin is the Interlock.

- The interlock pin is a critical safety feature. It sends a signal to the machine's controller to disable drive and lift functions while charging. A mismatch here is a huge safety hazard.

3. Match the Battery Chemistry Profile

The charger's output profile must match the type of batteries in the machine. Using the wrong profile will either undercharge the batteries, slashing their lifespan, or overcharge them and cause permanent damage.

- Action: Visually inspect the batteries to confirm their type.

- Flooded Lead-Acid: Requires a multi-stage profile with an equalization phase.

- AGM (Absorbent Glass Mat): Requires a specific profile that avoids high voltages that can damage the sensitive mats.

- Lithium (LiFePO4): Requires a charger with a specific lithium profile and the ability to communicate with the Battery Management System (BMS) over CAN-Bus.

Note: Components may vary by Gen 1 vs Gen 2 series. Verify with your parts manual.

4. Confirm Physical Mounting and Harness Length

The new charger must physically fit and bolt down properly. Vibration is the silent killer of electronics on construction equipment.

- Action: Do a side-by-side comparison of the old charger and the new one.

- Mounting: Ensure the replacement bolts securely into the original location. If it's loose, vibration will eventually cause a premature failure.

- Harness Length: Check that the AC input cord and DC output harness are the correct length. A harness that's too short is useless, and one that's too long can get pinched or rub against hydraulic lines, creating a dangerous short.

The Part You Need

The biggest headache with a failed charger is the six-to-eight-week lead time you get from the dealer while your machine sits dead in the yard. The part you need is a high-quality universal charger built to the common 24V/30A specification that fits both Sinoboom and Zoomlion electric scissor lifts. This Delta-Q charger profile works for both LGMG and Sinoboom as well as many Zoomlion models.

These aftermarket chargers are engineered as direct-fit replacements, often with more robust internal components than the OEM parts, built to handle the vibration and dust of a real job site.

China Lift Supply stocks these universal compatible universal chargers in the US to avoid the 6-week dealer lead time. Instead of managing separate part numbers for Sinoboom, Zoomlion, LGMG, and Dingli, you stock one unit that covers them all.

Avoiding Common Pitfalls

<iframe width="100%" style="aspect-ratio: 16 / 9;" src="https://www.youtube.com/embed/nvxkaqxeXsM" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>Getting a machine back online means doing the job right the first time. I’ve seen too many mechanics create more work for themselves by skipping basic checks.

The single most common error is blaming a failed charger for a bad battery pack. A new charger can't bring dead or sulfated batteries back to life.

- Action: Before ordering a replacement, use a load tester to confirm the battery pack can still hold a charge under pressure. If it fails the load test, the batteries are your problem, not the charger.

- Another frequent pitfall is ignoring the charger interlock circuit. If the interlock relay or its wiring fails, the controller never gets the "okay to charge" signal, making a perfectly good charger look dead. Always check for voltage at the interlock pin.

- Never, ever use a charger with the wrong profile for your battery chemistry (e.g., an AGM charger on a LiFePO4 battery). This is a fast way to destroy a new set of batteries.

- Finally, mount the new unit securely. Vibration is the enemy. Use all original mounting points and tighten the hardware correctly. Refer to your specific service manual for torque values—do not overtighten.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: Sinoboom and Zoomlion Chargers In Stock.