The Quick Diagnosis: Your rental yard is losing money because LGMG lifts are down waiting on parts with 6-week lead times. The solution is to stock for frequency, not possibility. Focus your inventory on high-turnover wear items (joystick boots, E-stops) and mission-critical electrical parts (contactors, limit switches) that cause the most common failures. This turns downtime from weeks into hours.

Symptoms & Identification

A poorly stocked parts room leads to predictable symptoms that kill your rental revenue:

- Machine is down for a "simple fix": A lift is dead in the yard for days, waiting on a $30 limit switch.

- Technicians are cannibalizing parts: Your mechanics are stealing parts from one dead machine to get another one running.

- High "hotshot" freight bills: You're constantly paying emergency shipping fees to get common parts overnighted from the dealer.

- Customers are complaining about downtime: Your most profitable clients are getting angry because a machine failed on their job site and the repair is taking too long.

If you're seeing this, your parts inventory strategy is broken.

Your LGMG Parts Strategy: Beat the 6-Week Wait

Every machine parked in the yard waiting for a part is a direct hit to your bottom line. The enemy is downtime, and its biggest ally is the 4 to 6-week dealer lead time for a component that should have been on your shelf.

A smart essential LGMG parts stocking list turns your parts room from a cost center into a strategic asset that keeps your fleet generating revenue. Waiting for a dealer shipment from overseas is not a viable business model. China Lift Supply stocks the parts you need in the US, so you can get them fast.

This guide organizes parts into a tiered matrix. It shows you which parts cause the most frequent problems and result in the longest downtime, guiding you on where to invest your parts budget for the biggest impact.

Tiered LGMG Stocking Priority Matrix

| Priority Tier | Part Category | Common Failure Examples | Downtime Impact | | :--- | :--- | :--- | :--- | | Tier 1 (High Priority) | Wear & Electrical | Joystick Boots, E-Stops, Limit Switches, Contactors, Fuses | High (Immediate Inoperability) | | Tier 2 (Medium Priority) | Hydraulic & Safety | Hydraulic Filters, Holding Valve Coils, Decals, Horns | Medium (Function Impaired or Unsafe) | | Tier 3 (Lower Priority) | Drive & Structural | Drive Motor Brushes, Seal Kits, Wheel Nuts, Platform Pins | Low to Medium (Planned Maintenance) |

This tiered approach focuses your capital on the parts that deliver the highest return by slashing downtime. Proactive parts stocking isn't about preventing every failure—that’s impossible. It's about ensuring that when a common failure does happen, the fix is measured in hours, not weeks.

For a deeper look into diagnosing specific issues, you can learn more about LGMG troubleshooting in our comprehensive guides. Keeping these critical spares on hand protects your rental revenue and keeps your customers happy.

Tier 1 High-Frequency Wear Parts

These are the non-negotiables. The highest-turnover parts that trigger the most service calls and will ground your machines if you don't have them on the shelf. These small, inexpensive items are your first line of defense against costly downtime.

Stocking these isn't a suggestion; it's the bedrock of a functional maintenance program. These parts wear out predictably, and waiting for them to fail on a job site is asking for trouble. A smart essential LGMG parts stocking list for rental yards always starts here.

Joystick Boots

The rubber boot at the base of a joystick is the only thing protecting its sensitive electronics from water, dirt, and hydraulic oil. The second that boot cracks, contamination is guaranteed.

Once contaminated, a joystick develops erratic movements before failing completely. This cheap part saves you from a much bigger headache. Check for cracks during every pre-delivery inspection (PDI).

Non-Marking Tires and Wheels

For any slab scissor working indoors, non-marking tires are a must. They're under constant assault from abrasion and chunking. A machine with damaged tires is a safety hazard that will get sent right back by any competent site manager.

Keep a full set of wheels on hand for your common models. Swapping a complete wheel assembly is faster than pressing a new tire onto an old rim. You get the machine back on rent in minutes, not hours.

Platform Entry Chains and Latches

The spring-loaded latches and chains on platform gates take a beating. They're used constantly and often abused. Look for stretched links, weak springs, and broken latch mechanisms. A missing or faulty entry chain is a blatant OSHA violation that can get a job site shut down.

A failed gate latch isn't an inconvenience; it's a liability. If an operator can't secure the platform entry, the machine is legally unusable. Don't let a $20 part cost you thousands in lost rental revenue.

Safety and Capacity Decals

Decals are legally required safety information. Pressure washing, sun exposure, and wear will make them unreadable. If your capacity, warning, or operational decals are illegible, that machine will fail its annual inspection. Keep a complete decal kit for each model in your fleet.

The Part You Need

Having these fundamental wear items ready is good business. China Lift Supply stocks a huge inventory of these and other universal LGMG parts in the US, so you can get what you need without the long dealer delays.

Tier 2: Mission-Critical Electrical Components

When an LGMG lift stops cold, the electrical system is the first place to look. One bad switch or a faulty contactor can turn a working machine into a dead one.

These Tier 2 parts will shut a machine down instantly. They don't fail as often as wear items, but when they do, the machine is out of commission. Having these on the shelf is the difference between a multi-day diagnostic nightmare and a same-day repair. This is where a solid essential LGMG parts stocking list for rental yards earns its keep.

Universal Joysticks and Controllers

The joystick is the central command. When one goes bad, you'll see symptoms like a specific function not responding or a total freeze on all movement. Many LGMG models use universal-style joysticks, so stocking one or two can cover a range of your scissor lifts.

A bad controller will cripple a machine just as fast, making it a must-have spare.

Emergency Stop Switches (E-Stops)

The E-stop is a vital safety component. If an operator calls saying the machine won't power on, the first things to check are the E-stop and the key switch. Their internal contacts wear out or break, creating an open circuit that kills power to the controller.

A failed E-stop is an easy diagnosis. If you've pulled the button out and still get no power, it's the culprit. Having a spare turns a critical failure into a ten-minute fix.

Contactors and Solenoids

Contactors are heavy-duty relays that handle high-amperage current for the main power system and hydraulic pump motor. When a contactor fails, you might hear a 'click' but get no action, or the machine may not power on at all. The contacts inside get pitted or fused over time.

A tech can test a contactor in minutes with a multimeter. Stocking the main power contactor is a smart move; its failure takes the entire machine offline.

Limit and Tilt Switches

These small switches tell the controller critical information—like when the platform is stowed or if the machine is on an unsafe slope. A failed pothole limit switch might prevent driving at full height. A bad tilt sensor will throw a fault code and disable all functions.

The Part You Need

Downtime is a profit killer. Industry data shows that control joysticks account for 18% of all technician calls. Stocking these Tier 2 electrical parts is a direct investment in uptime. Waiting weeks for a switch is unacceptable when you can find a huge range of compatible LGMG electrical components right here in the US, shipped same-day from China Lift Supply.

Tier 3: Essential Hydraulic and Drive System Spares

Hydraulic and drive system failures are the big ones. A blown hose or a dead drive motor stops a machine cold, often in the worst possible spot. These failures kill rental revenue and create serious safety headaches.

While you won't replace these parts as often, a breakdown here can lead to your most expensive repairs. Stocking these Tier 3 spares is insurance against major downtime—a critical part of any smart LGMG parts stocking strategy for a rental yard.

Hydraulic Pump Seals and Seal Kits

The hydraulic pump is the heart of your lift. Once a pump seal fails, you’ll see a drip or a steady stream of hydraulic fluid. Ignoring a small leak leads to catastrophic pump failure from fluid starvation and contamination.

Having a complete pump seal kit on the shelf means a good mechanic can rebuild that pump in-house in hours, which is better than waiting weeks for a new pump assembly.

Holding Valve Coils and Cartridges

Symptom: Scissor lift is "creeping down" or a boom won't hold its position. Cause: A bypassing holding valve is almost always the culprit. The electrical coil can burn out, or the internal seals on the valve cartridge can fail, letting fluid seep past.

- Quick Test: Check for voltage at the coil when the function is activated. If you have power but no action, the coil is the likely suspect.

- The Fix: The coil is often a quick swap. If that doesn't solve it, the entire valve cartridge needs replacing. Keep both on hand.

Drive Motor Brushes

Electric drive motors rely on carbon brushes to get power to the armature; these brushes are designed to wear out. As they get thin, the motor loses torque, causing sluggish driving or pulling to one side. Eventually, it won't drive at all. On LGMG lifts, drive motor brushes typically need replacing around the 1,200-hour mark, making them a predictable and essential spare part. You can read the full research on equipment market trends to see how these failures impact rental operations.

Common Hydraulic Hoses

You can’t stock every hose for every machine, but you can identify the high-risk ones. Look for hoses that see the most movement and flexing—like steer cylinders or the main lift cylinder. A visual inspection during PDI often reveals hoses that are cracking, bulging, or abraded.

Stocking the top two or three most common hose assemblies for your high-volume models will save you from a panicked call to a local hose shop.

The Part You Need

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: [Link Placeholder].

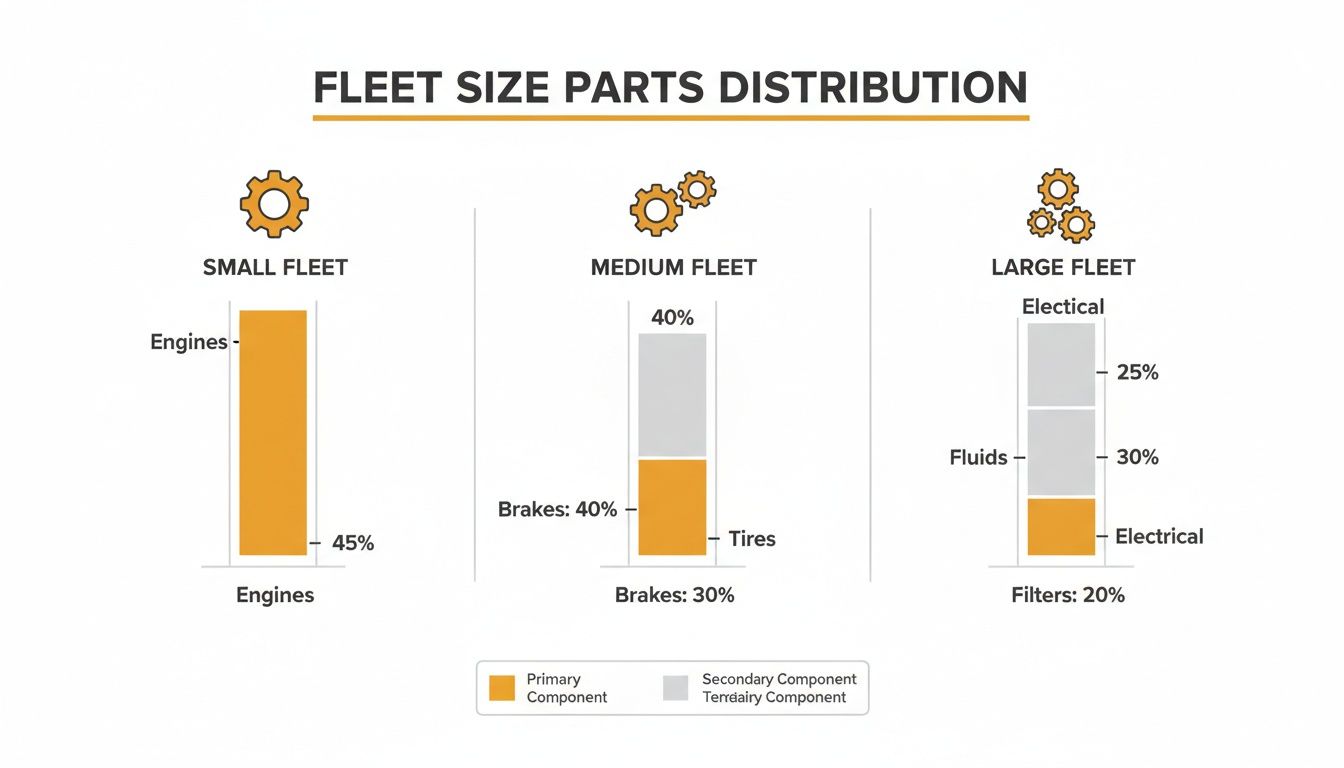

How to Scale Your LGMG Parts Stock by Fleet Size

A one-size-fits-all parts list either ties up cash in parts you won't use or leaves you scrambling. Your stocking strategy must scale with your fleet.

What a 15-machine yard needs is different from a 150-machine operation. This is a practical guide to building an essential LGMG parts stocking list for rental yards that works. As your fleet grows, your strategy shifts from covering frequent failures to building depth in mission-critical components.

LGMG Parts Stocking Quantities by Fleet Size

This table provides recommended on-hand quantities for essential LGMG parts based on the number of machines in your rental fleet.

| Part Name | Part Category | Small Fleet (1-20 Units) | Medium Fleet (21-100 Units) | Large Fleet (101+ Units) | | :--- | :--- | :--- | :--- | :--- | | Joystick Boots | Wear & Tear | 5-10 | 15-20 | 25+ | | E-Stop Switches | Safety | 2-3 | 5-7 | 10-12 | | Decal Kits | Safety | 2 Kits | 5 Kits | 10 Kits | | Platform Chains/Latches | Wear & Tear | 3-4 Assemblies | 8-10 Assemblies | 15+ Assemblies | | Universal Joysticks | Electrical | 1 | 3-5 | 10-15 | | Contactors | Electrical | 1-2 | 4-6 | 12+ | | Holding Valve Coils | Hydraulic | 1-2 | 5-7 | 15-20 | | Drive Motor Brush Sets | Drive | 0-1 Set | 2-4 Sets | 6-8 Sets |

These numbers are a starting point. Adjust them based on your fleet's usage patterns and model mix.

Small Fleet (1-20 LGMG Units)

Focus on high-frequency, low-cost wear parts. The goal is to stop the most common downtime without overstocking.

- Joystick Boots: Cheap insurance. Keep 5-10 on hand.

- E-Stop Switches: A must. Stock 2-3 universal E-stops.

- Decal Kits: Have 2 complete kits for your popular models.

- Platform Chains/Latches: They fail constantly. Keep 3-4 assemblies ready.

Medium Fleet (21-100 LGMG Units)

You'll see a wider variety of breakdowns. Stock all Tier 1 items in higher quantities and add critical Tier 2 electrical and Tier 3 hydraulic parts.

- Universal Joysticks: Your first defense against electrical problems. Stock 3-5 of the most common type.

- Contactors: When a main power contactor fails, the machine is dead. Having 4-6 on the shelf is non-negotiable.

- Holding Valve Coils: A "creeping down" call can be a 15-minute fix. Keep 5-7 coils ready.

- Drive Motor Brush Sets: Motors show age around 1,200 hours. Stock 2-4 complete sets.

Large Fleet (101+ LGMG Units)

Your parts room must handle several machines going down at once. Stock all Tier 1 and 2 parts in significant numbers and add strategic Tier 3 spares. Your parts room should operate like a dedicated distribution hub, because the cost of one grounded machine for a week far outweighs the cost of a part on the shelf.

Stock at least 10-15 universal joysticks, a dozen contactors, and a deep inventory of every wear item. It's also time to stock 2-3 complete hydraulic seal kits for common pump models and even a few pre-made hydraulic hose assemblies for the ones that always fail on a Friday afternoon.

Essential Safety and Compliance Components

Safety is non-negotiable. Sending a machine out with a busted horn or faulty E-stop is a massive liability. This isn't about uptime; it's about protecting operators and your business. A dead strobe light might seem small, but on a noisy job site, it's a critical failure that could get your customer flagged by OSHA.

Key Safety and Compliance Spares

Keeping these parts on the shelf is the cheapest insurance you can buy.

- Horns and Alarms: The travel alarm is a must-have. If it’s silent, the lift isn't safe. Stock a few universal-fit models.

- Strobe Lights and Beacons: Crucial in loud environments. A cracked lens or burnt-out bulb needs to be replaced immediately.

- Lanyard Anchor Points: A bent or cracked anchor point is a critical failure of the fall protection system. Refer to your specific service manual for torque values—do not overtighten.

- Safety Harnesses: Keeping a few new, certified harnesses in stock can save the day for a customer. Track expiration dates.

Pre-Delivery Inspection Checklist for Safety

Every LGMG lift needs a rigorous safety check before it leaves the yard.

Don't let a $5 part create a $50,000 liability. A machine with a silent travel alarm or a broken E-stop isn't just broken; it's a hazard. If it's not 100% compliant, it doesn't leave the yard.

Your PDI must confirm:

- E-Stop Buttons: Test both platform and ground controls.

- Horn and Travel Alarm: Loud and clear.

- Strobe/Beacon: Flashes correctly, lens intact.

- Lanyard Anchor Points: Visually inspect for cracks or damage.

- Safety Decals: All labels present and legible.

- Gate Latches/Chains: Lock securely.

Stocking these simple safety parts is a direct investment in your company’s reputation.

Optimizing Your Parts Room for Rapid Repairs

Having the right parts means nothing if your tech can't find them. A disorganized parts room causes extended downtime. The goal is to set up a system where a mechanic can grab the correct component in under two minutes. A solid parts room workflow is a core piece of an efficient essential LGMG parts stocking list for rental yards.

Implement a Clear Labeling System

Your bins need to tell a story. Vague labels like "LGMG Parts" are useless. An effective label needs three things:

- Part Number: The OEM or cross-referenced number.

- Part Description: A simple name (e.g., "E-Stop Switch, Twist-to-Release").

- Machine Model Compatibility: List the specific LGMG models this part fits (e.g., "Fits: AS0607, AS0808").

This system ensures the right part gets pulled the first time.

Establish a First-In, First-Out (FIFO) System

Parts don't last forever. The joystick sitting in the back of the bin for three years is more likely to fail than the new one. When new stock arrives, put it at the back of the bin. This forces techs to pull the oldest stock from the front first, ensuring you use parts before they degrade.

A well-organized parts room is a weapon against downtime. Every second saved finding a part is a second closer to getting that machine back on the rent roll. A chaotic system actively costs you money.

Set Minimum Reorder Points

Don't wait until you're out of a critical part. Set a minimum reorder point for every part you stock. If your minimum for a limit switch is three units, the moment a tech pulls one and you're down to two, that's your trigger to order more. This proactive approach automates procurement and prevents stockouts.

Frequently Asked Questions About Stocking LGMG Parts

Here are the straight answers to the questions we get all the time.

Why Should I Tie Up Capital in Parts Inventory?

You aren't "tying up capital"; you're insuring your rental revenue against downtime. A single LGMG lift idle for a week waiting on a $50 part can cost you over $500 in lost rent. That one incident pays for your entire stock of that part. The real capital is tied up in the $100,000 machine generating zero income.

A curated essential LGMG parts stocking list for rental yards is a high-return investment in uptime.

Can I Just Use Cheaper Universal Parts?

Yes, but you must know what you’re buying. A "universal" part isn't automatically low-quality. Components like joystick boots and E-stops are often made by the same factories that supply the OEM. The secret is verified compatibility.

The danger is in unverified, "looks-the-same" parts. A joystick might have the same plug, but if its internal resistance is off, it can fry the main controller.

Always source aftermarket parts from a supplier who understands Chinese-made equipment and can guarantee the component is correct for your LGMG model. A cheap part that doesn't work is the most expensive part you can buy.

I Am Starting from Scratch, Where Do I Begin?

Follow this three-step plan:

- Buy the Tier 1 Essentials: Start with high-frequency wear items. Order five each: joystick boots, platform entry chains, and key switches. Add two universal E-stops and a couple of decal kits for your most common models.

- Talk to Your Techs: Ask them, "What are the top three parts you've had to wait on in the last six months?" Their answers are your immediate Tier 2 stocking priorities.

- Track Your Next 10 Breakdowns: Get a whiteboard. For the next ten service calls, write down the part that failed. This real-world data is gold. It will show you your fleet's weak points and tell you what to add next.

This approach builds your inventory based on actual need, not guesswork.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: https://www.chinaliftsupply.com.