When the OEM charger on your Dingli, LGMG, or Sinoboom lift quits, you're losing money. The fix is a programmable, multi-chemistry aftermarket charger from a brand like Delta-Q or a high-quality Schauer. These let you dial in the exact algorithm for Flooded Lead-Acid, AGM, or Gel batteries, which prevents damage and extends the life of a very expensive battery pack.

The Quick Diagnosis

A dead charger means a dead machine. Most factory chargers on Chinese lifts are basic, single-chemistry units that can't handle a tough rental environment. The fastest solution is a universal aftermarket charger that matches your voltage (24V), amperage (20-25A), and connector (usually an SB50). Don't wait 6 weeks for an OEM part—swap in an upgrade and get running tonight.

Symptoms & Identification

- Charger has no lights at all (and you've confirmed the AC outlet works).

- Charger is flashing a constant Red light or an alternating Red-Green-Red sequence, indicating an internal fault.

- The machine’s battery gauge never reaches 100% charge, even overnight.

- You smell sulfur (rotten eggs) or see acid residue on top of the batteries, a sign of severe overcharging.

Tools Required

- Multimeter

- Metric Socket Set (10mm - 17mm)

- Wire Strippers/Crimpers (if swapping connectors)

- Safety Glasses

Safety Warning

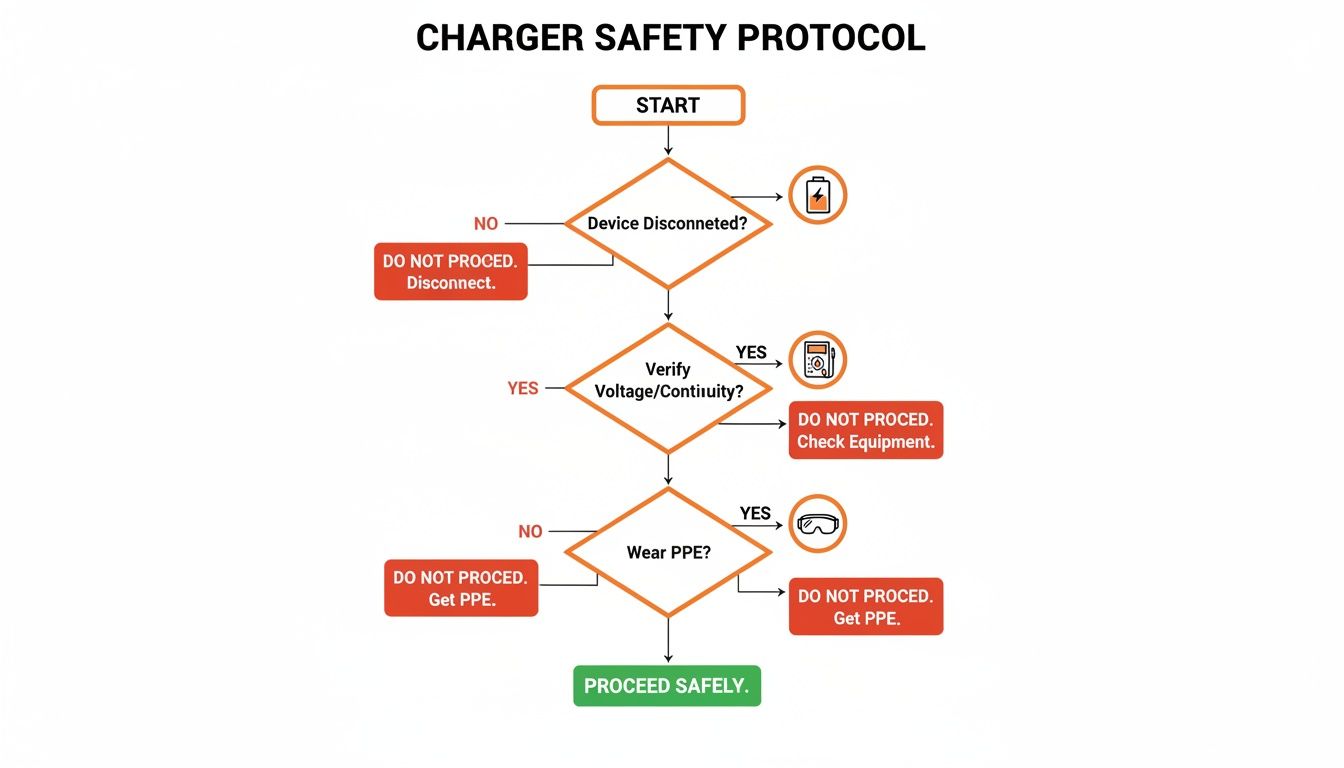

Disconnect the main negative battery terminal from the battery pack before unplugging or unbolting the old charger. This breaks the circuit and eliminates the risk of an arc flash from a short circuit.

The Technical Guide (Charger Swap & Verification)

Before you order a new charger, be 100% sure the old one is the culprit. A faulty charger can mimic a bad battery or a loose wire. Throwing parts at a lift wastes time.

Step 1: Confirming the Charger is the Problem

Most chargers will tell you what's wrong with their diagnostic lights.

- Constant Red Flash: Usually means an internal fault on the charger's control board. It failed its own power-on self-test.

- Alternating Red-Green Blink: Often means the charger can't sense the battery pack correctly or the voltage is too low to initiate a charge. This points to a failed internal component.

- No Lights at All: If your AC outlet is live, a dark charger indicates a blown internal fuse or a fried power supply.

- Loud Humming with No Output: If the charger hums but the ammeter shows zero current, the transformer or rectifier has likely failed.

A failing charger doesn't just die; it becomes a threat to your expensive battery pack. Undercharging leads to sulfation, and overcharging will cook the batteries, destroying them. If you see these symptoms, the charger is the root cause. For deeper electrical tests, our troubleshooting guides can help.

Step 2: Matching the Aftermarket Charger

<iframe width="100%" style="aspect-ratio: 16 / 9;" src="https://www.youtube.com/embed/bFI64_pFpUQ" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe> Getting this part wrong means you’ve bought a paperweight or you’re about to cook a battery pack. Get these four checks right.- Voltage and Amperage: The system is 24V. The charger output must be 24V. No exceptions. For the battery packs in most Chinese scissor lifts, a 20A to 25A charger is the correct size.

- Battery Chemistry Profile: This is critical. A stock charger set for flooded lead-acid (FLA) batteries will destroy sealed AGM or Gel batteries by overcharging them. A quality aftermarket charger is programmable. You must select the correct algorithm for your battery type.

| Battery Type | Common Brands (Trojan, U.S. Battery) | Required Charging Profile | Risk of Using Incorrect Profile | | :--- | :--- | :--- | :--- | | Flooded Lead-Acid (FLA) | T-105, J305 | Standard Flooded/Wet profile | Undercharges an AGM/Gel; leads to sulfation buildup. | | AGM (Absorbed Glass Mat) | T-105 AGM, Reliant AGM | Specific AGM profile with lower float voltage | Severe overcharging, gassing, and dry-out if using an FLA profile. | | Gel | 31-GEL | Specific Gel profile | Overcharging and permanent damage to the gel electrolyte. |

- Connector and CAN-Bus: Over 90% of Chinese lifts use a gray Anderson SB50 connector. Verify this on your machine. For most of these lifts, CAN-Bus communication is not required. The charger operates as a standalone unit, simplifying the swap.

- Physical Fit and Durability: Check the mounting pattern to ensure the new charger's bolt holes line up. More importantly, check the IP Rating. A charger with an IP66 rating is sealed against dust and high-pressure water, making it suitable for tough job sites. A lower-rated charger won't last.

Step 3: Installation and Testing

Follow this process exactly. This is a 30-minute job.

- Power Down: Turn the key off. Disconnect the main negative battery terminal. Unplug the old charger from the wall and the machine. Unbolt the old charger and save the mounting hardware.

- Mount New Unit: Secure the new charger using the old hardware. Refer to your specific service manual for torque values—do not overtighten.

- Connect and Power Up: Plug the new charger’s DC cord into the lift's charge port. Reconnect the main negative battery terminal, ensuring a clean, tight connection. Plug the charger's AC cord into a known-good wall outlet.

- Verify Operation: The charger's indicator lights should switch to charging mode (e.g., solid amber or flashing green). Set your multimeter to DC Volts and check the battery terminals. You should see a voltage reading above nominal (e.g., 25.5V or higher) that is slowly climbing. This confirms current is flowing.

If you need mounting hardware or a replacement connector, our catalog of lift and forklift parts has it.

The Part You Need

The biggest enemy is downtime. Waiting 6 to 8 weeks for an OEM charger from China is not an option. A top-tier universal charger from a brand like Delta-Q is engineered to be a direct, superior replacement for equipment from Dingli, LGMG, and Sinoboom.

China Lift Supply stocks these exact OEM-compatible universal 24V aftermarket chargers for Chinese lifts in the US to avoid the 6-week dealer lead time. When you order, it ships from Kansas the same day.

Shop Talk: Common Questions

- Will an aftermarket charger void my warranty? No. In the U.S., the Magnuson-Moss Warranty Act prevents this, as long as you use a quality part with the correct specs (24V, proper amperage, correct charge profile).

- Can I use a higher amp charger to charge faster? Bad idea. Using a 35A charger on a system designed for 20A generates excessive heat, which warps plates and cooks the electrolyte. You'll shorten the battery pack's life significantly. Stick to the recommended 20-25A range.

- Is CAN-Bus necessary? For the vast majority of these lifts, no. The charger is a standalone unit. This makes installation simple.

- What if I use the wrong charge profile? This is the fastest way to kill an expensive battery set. Using a standard FLA profile on an AGM battery will permanently damage it through overcharging. Always match the algorithm to the battery type.

Can't wait 6 weeks for this part? We have it on the shelf in Kansas. Check the price and availability here: https://www.chinaliftsupply.com.